MORE AGILE FOR YOU

Industrial marking solutions designed to meet each of your uses

Technomark is revolutionizing the world of industrial marking and changing the way you think. From now on, our teams are committed to associate your daily work with permanent marking solutions that correspond to each of your industrial uses.

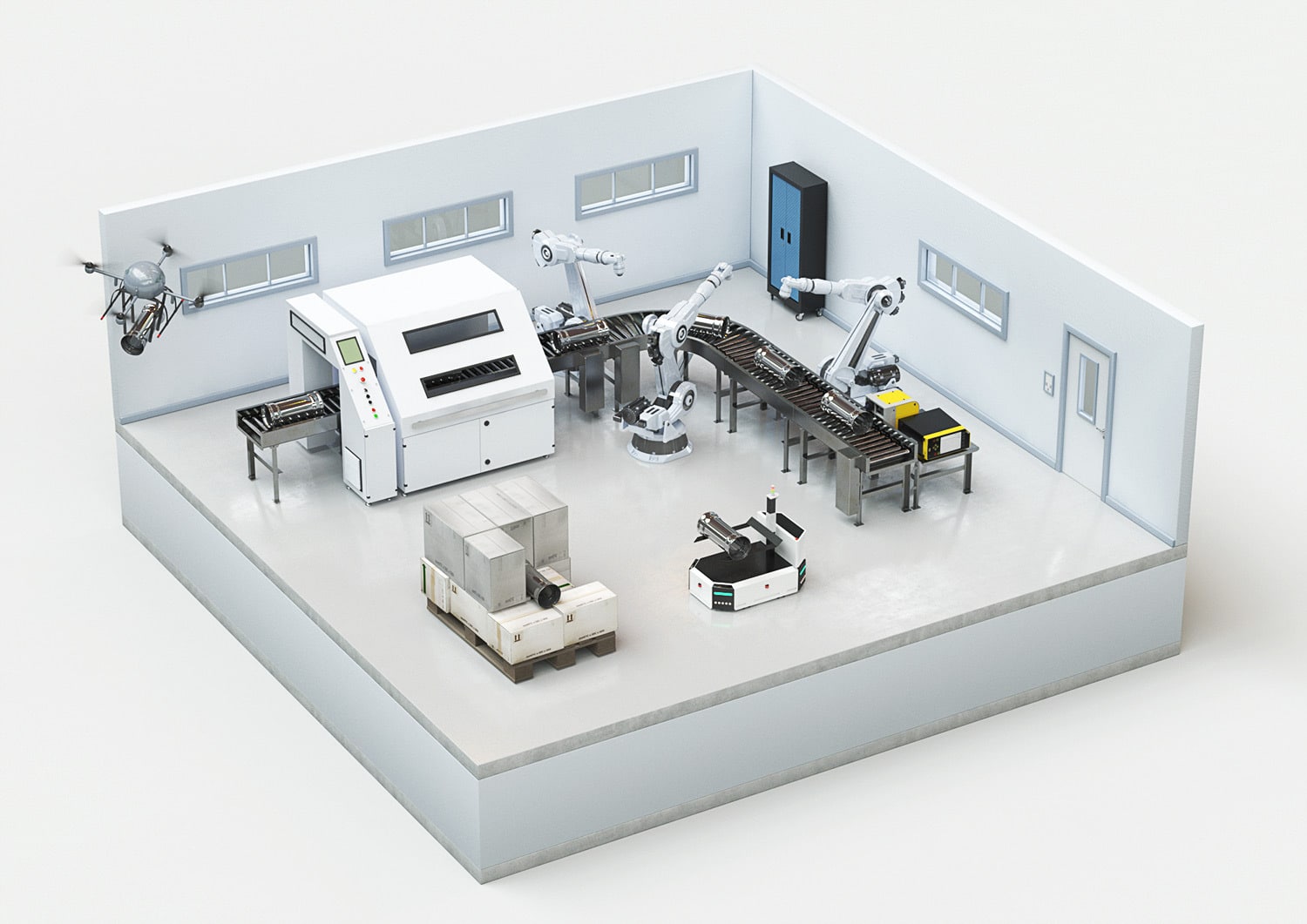

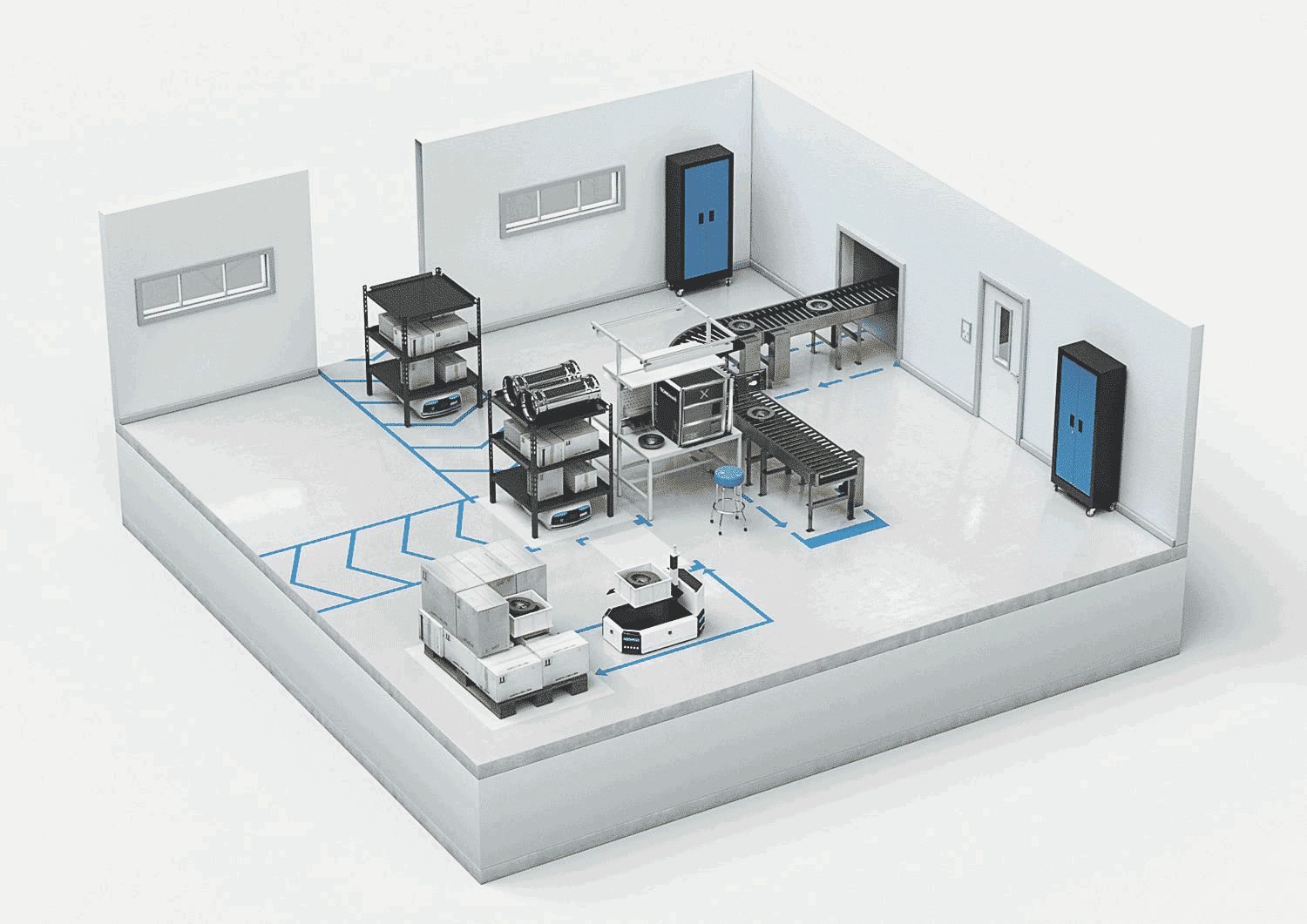

Whether your need for industrial traceability is for station, island production, mobile or even integrated use, Technomark has a permanent laser or dot peen marking solution for you.

technology

What technology for what use?

Technomark offers solutions based on two technologies: electromagnetic dot peen and fiber laser. Dot peen is ideal for all applications, while laser marking is more suited to integrated and stationary applications.

How do I choose my marking technology?

First of all, you need to know what type of marking you want to achieve. Dot peen technology marks by repeatedly impacting the part with its stylus. It then slightly deforms the material. This makes the marking permanent and unalterable. This is particularly useful for alphanumeric markings such as :

- serial numbers

- batch numbers

- time stamping

Laser technology uses its laser beam to heat and/or remove material in order to engrave the part. It’s a highly precise technology that produces clean, aesthetically pleasing markings.

It’s the ideal solution for marking logos. Setting the parameters of the laser source also offers other advantages. Depending on the materials to be marked, you can define different contrast levels on the same marking file.

It’s this feature, in particular, that enables you to produce ultra-readable Datamatrix. The first pass of the laser source brightens the area to be marked, while the second pass creates a dark engraving, so that it is more visible and easier to read.

marking and traceability

What are the challenges of industrial marking and traceability?

The opportunities offered by industrial marking and traceability are considerable. First and foremost, it’s a matter of collecting information, which can be very important for companies, customers who will be the future users of the products, but also for third-party entities (suppliers, resellers, etc.). All parties with access to the product throughout its life cycle can consult and contribute to the information.

Whatever the marking technique, dot peen or laser, and whatever the type of surface, the aim is to apply a permanent mark to the desired surface. Once the marking has been applied, there’s no need to worry about identifying an item. Marking is permanent, meaning it resists deterioration and falsification, unlike traditional labels or other marking solutions. It’s also worth noting that marking in no way alters the properties of materials, so they retain their technical characteristics.

applications and uses

When should you use industrial engraving?

Information and communication

The most common use of industrial marking is simply the inscription of basic information such as the company name and logo to promote the brand, batch and serial numbers to help different operators identify a part or product easily among many others that are similar.

This can be a very good means of communicating with end-users, for example, to provide contact details for the company’s after-sales service, to indicate the various mandatory standards that products comply with, to identify the various characteristics of parts such as the materials used or the treatments they have undergone, etc…

Protection and assurance of authenticity

In certain sectors, such as the sale of luxury goods, companies are trying to combat the counterfeiting of their products. Some of them use marking solutions to easily identify whether a product has actually been manufactured by the brand, and thus ensure its authenticity or not.

Identification, traceability and proactive product returns

Widely used in the automotive and aeronautics sectors, the engraving of parts to identify defects is important and sometimes mandatory. When a batch defect is identified, this enables all products affected by the same manufacturing problem to be identified in a minimum of time, and all customers to be located and contacted for a much faster product recall. It’s an application for protecting and anticipating problems that can sometimes be major.

Marking materials

Different types of engraving systems to suit your materials

Each customer has his or her own needs and constraints, particularly in terms of the material to be marked.

Engraving on metal / steel

From superficial to deep marking, our machines offer laser and dot peen marking. We offer different solutions for the following applications:

- Carters

- Blocs moteurs

- Châssis en acier peint…

Engraving on aluminum

Good marking must not damage the properties of aluminum parts (e.g. when deep engraving is carried out quickly without using maximum power).

You can mark :

- Aerospace parts

- Aluminum plates

- Gearboxes

- Carters…

Engraving on plastic parts

Engrave information such as logos, serial numbers or barcodes onto a variety of materials including PVC, polycarbonate, polyethylene and polypropylene.

Marking technologies developed by Technomark

| Laser marking |

Dot peen marking | |

|---|---|---|

| Concept | Uses a laser beam to engrave the surface of the object | Uses a carbide stylus to create dot peen impacts on the surface |

| Marking depth |

Can mark superficially or deeply, depending on the material | Creates deep, permanent marks |

| Marking speed |

Fast, suitable for large quantities | Slower than laser marking, more suitable for short production series |

| Suitable materials | Suitable for a wide range of materials, including metals, plastics and ceramics | Particularly suitable for hard surfaces such as metals and alloys |

| Application | Ideal for QR codes, serial numbers, logos and texts | Recommended for applications requiring high wear resistance |

| Benefits |

|

|

What is the benefit of industrial marking?

The purpose of industrial engraving is to permanently mark parts or products to identify or protect them. It enables additional information to be added, such as the manufacturer, serial number, technical specifications or production date.

What is workshop marking?

Industrial marking is a method used to identify and mark manufactured products to guarantee their authenticity and conformity to industry rules and standards. It is an important step in product manufacturing and quality control.