Materials

Laser marking on aluminium

Characteristics

Aluminium marking solution

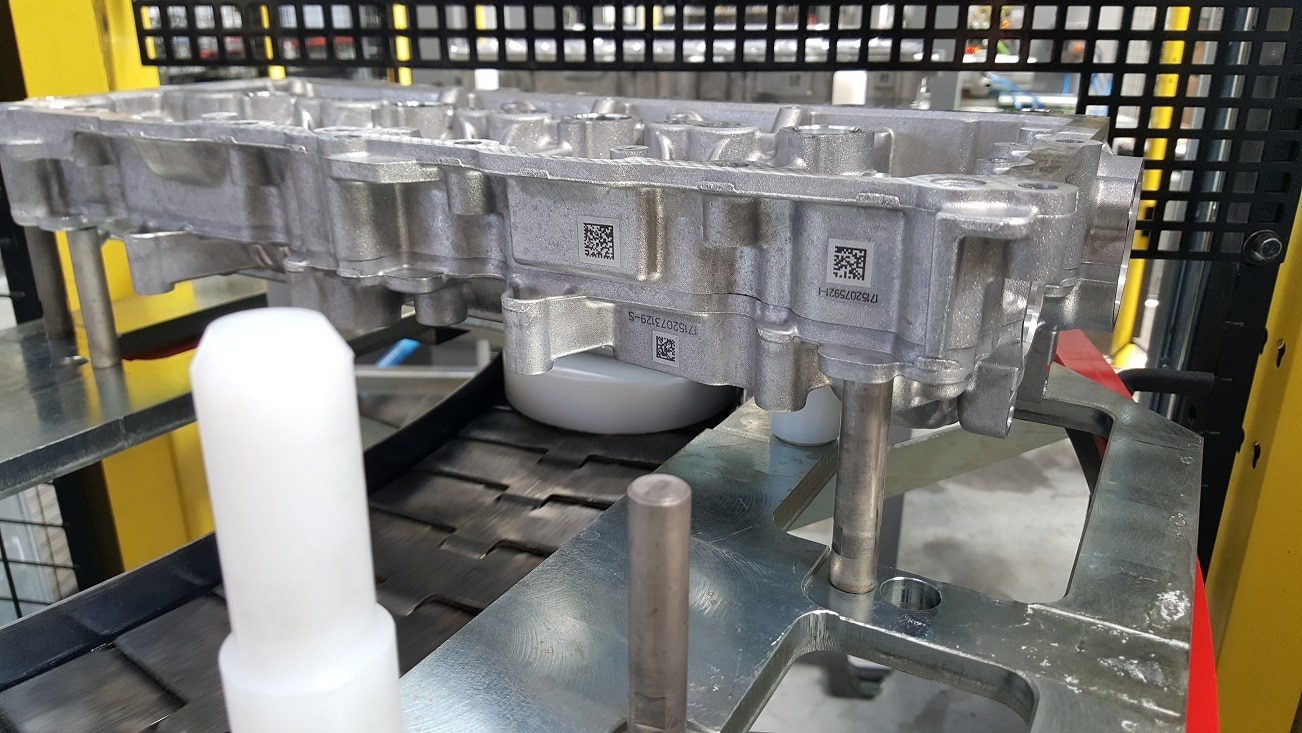

Three sets consisting of GRAPHIX Inline 20W marking lasers and DATALOGIC Matrix 300N readers are on the production lines. This equipment ensures the traceability of the camshaft housings in aluminium casting. Each station is designed as follows:

- A laser protection enclosure positioned above a conveyor with an access hatch from below.

- The camshaft bearings are conveyed on pallets and stopped under the laser station.

- A jack (up and down) positions the tool in the marking area with the part in the station. The station is then safe, and the part is marked.

If the marking is validated after proofreading the Datamatrix code, the part is cleared out.

Otherwise, the marking is erased by laser overlap, then marked again.

The laser is controlled via the Ethernet TCP-IP communication protocol. The complete cycle is managed by the line PLC.

Discover various automotive marking applications

Technical details

Cycle time

20 to 30 seconds

Type of marking

Two marking zones with control of a Z axis