You have a laser engraver needs and you don’t know how to choose your solution?

It’s difficult to choose the best engraving machine among the available offer on the market but first you should take stocks of your needs and projects requirements. You may not choose the same laser engraver depending on the parts to be marked or the desired result.

To help you answer those questions, we work together on your marking project with our Technomark sales and technical teams. Primary you may know the nature of the parts to be marked i.e. their shapes, their size and their materials. Then you have to consider the marking type you need to realize and its marking pace.

Let’s take the time to study your needs and define your requirements to built together you traceability project. We will choose together the best solution for your use with the best value for money.

Why choose a laser engraver?

There are many advantages to choose laser technology. It allows make silencer markings with an high speed performance. Without direct contact with the material you don’t need to clamp the part. It also allows to avoid the beginning of a break which is requested in various sectors like aeronautical for example. The marking possibilities are numerous.

Alphanumerical marking

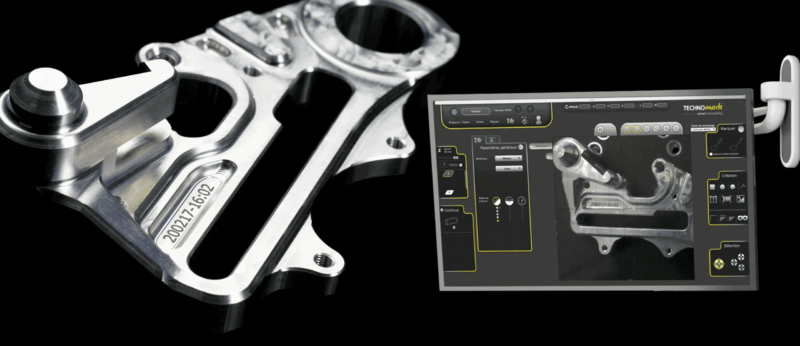

It is possible to mark alphanumerical text, in a manual or automatic way using serial numbers and time stamps.

Barcodes and 2D codes for product traceability

To insert even more information in a very small area, operators often use 2D codes or barcodes. The Datamatrix, which is the most widely used format, is easily readable via smartphone and has a high reading tolerance despite a deterioration of the marking. The markings are of high quality, which can meet a simple need for traceability.

Engraving of logos and visuals to mention the standards and get an aesthetic aspect

We can also meet the aesthetic finishes through the realization of marking logos or visuals for example. The rendering can be contrasted and sometimes even shaded depending on the materials.

Find out more informations about laser technology

Which type of laser to choose?

There are several industrial laser technologies on the market which cover various needs : cutting, welding, marking and engraving (which is almost the same). Technomark is a manufacturer of marking and engraving laser. Industrial marking could be done with various lasers : CO2 laser, green laser, crystal laser, UV laser and then fiber laser.

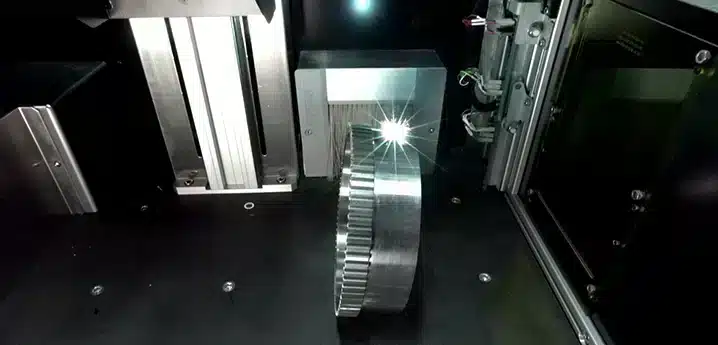

Focus on Graphix.series

Our laser from the Graphix.series range are available in various configurations : for a station use or an integrated use. They offer a fiber laser technology with a wavelenght between 1060 and 1085 nm which allows to mark a lot of materials : all the ferrous metals or not and most of the platics.

Support for your project

According to your needs, we make a faisability study and marking tests to confirm together the desired result. We can mark every material type except the organic ones.

Aluminium, steel, stainless steel, precious metals, iron, copper, the renderings are very different and depend on the material. It is important to trust our sales and technical team in marking test making directly on your parts. We can make these free trials on site or in our office.

What are the benefits to choose the Technomark fiber laser engraver?

From 20 years we have a significant experience in traceability and we have put it all into our new laser marking range Graphix.series for a very easy and intuitive use. Available in two versions : station use ou integrated use (with the Graphix Inline), our laser will meet all your traceability needs.

Our laser marking station Graphix has the best performance/quality/value for money on the market.French fab certified, our laser are designed and made in France and our team support you during all the product life. Support is in our DNA, Technomark put all its energy to satisfy customers and partners both before and after sales.

Today Technomark is democratising laser marking thanks to its very intuitive software created with Linux OS and all its functions which made the difference in everyday life.The all-in-one station, our Graphix laser engraver offer you easy to make and quick markings. You just have to put the parts in the station, setting up the marking and launch it to see your parts engraved.

Mark in a just a few seconds

Just a few seconds are needed to see the permanent marking directly on your parts. Its high loading capacity of 500*500*400mm and its digital Z-axis controlled allow to mark parts from very little dimensions to medium size. For large parts you can have a simple or double side opening.

Innovative thanks to its intelligent and ergonomic software

The on-board camera and its Smart View function allows the direct view on the part being marked directly on the screen thanks to augmented reality. Its setting software with friendly design and intuitive functions offer 3 levels of users : from the novice one to the expert. It allows to fine-tune the marking or to have an access to a database with materials and desired renderings to set-up easily and launch the marking. So, everybody can make a marking on its part in a few clicks.

Codes, used every minutes in the industry world, are also very easy to create thanks to the software. You have to mark Datamatrix code? You can make compliants with standards ones directly in the software. The little extra: you can also inverts it in 1 click.

A solution designed for your needs

Our solution is also customizable to meet all your needs and offer you a turn-key all-in-one solution.

You’re also interested in our customizable solutions ? Find out more informations about customization