Technomark > Datamatrix and 2D code marking

Datamatrix and 2D code marking

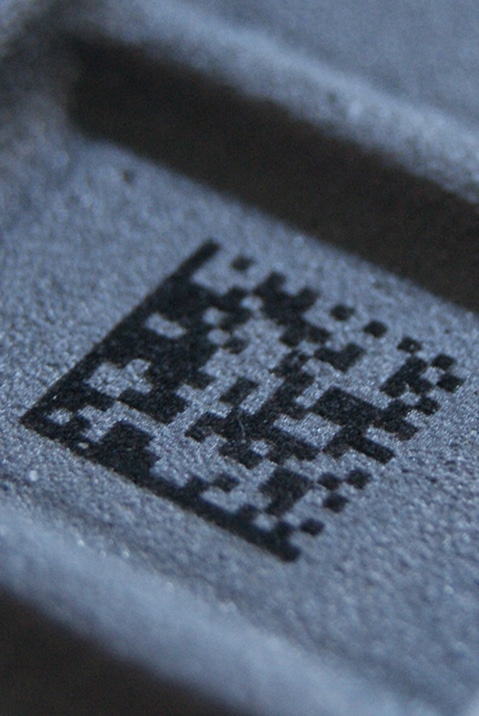

encoded markings

Datamatrix code marking, an industry essential

The Datamatrix code is a 2D code that can be used to encode large quantities of information. Its use is widely democratized in many industrial sectors, but varies from continent to continent. This type of 2D code complies with the ISO / IEC 16022 standard, and is therefore freely available in the public domain.

In Europe and the USA, Datamatrix marking is the universally recognized encoding technique for DPM (Direct Part Marking).

QR codes are also used in Asia, particularly Japan.

There are many types of Datamatrix markings:

- ECC200 is the most widely used code in the industry.

- The GS1 variants, macro05 and macro06, are mainly used in aeronautics, and enable additional data to be encapsulated. More specifically, GS1 Datamatrix marking enables the data it contains to be structured and segmented using prepositions located before each of the contents.

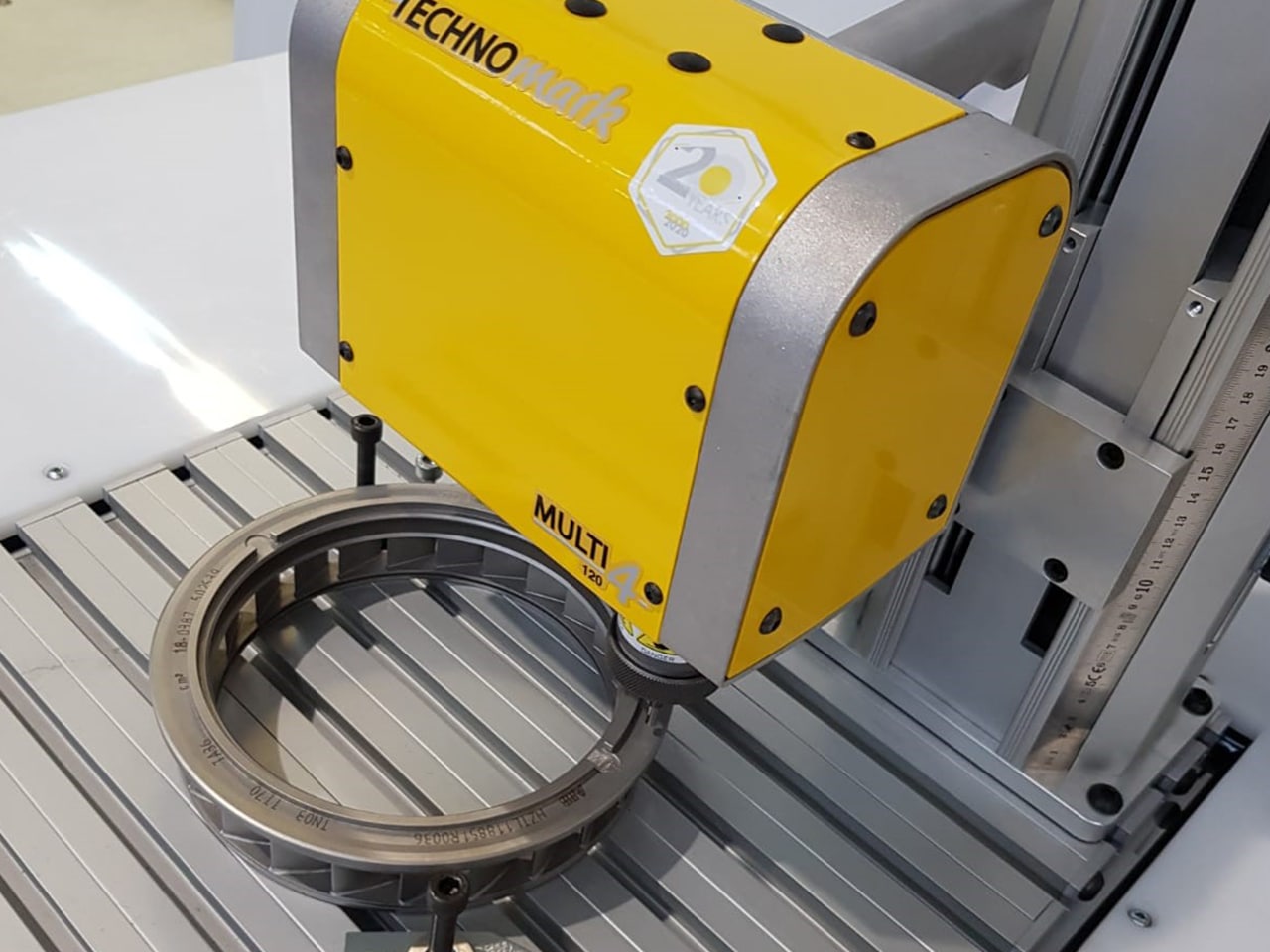

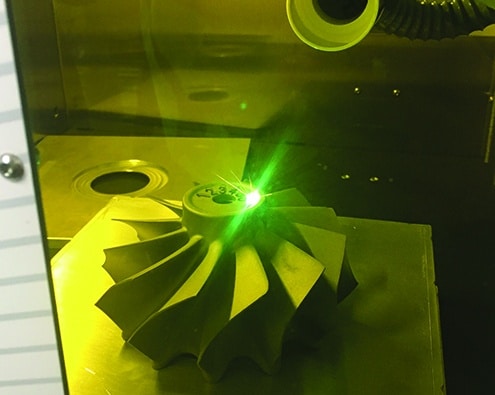

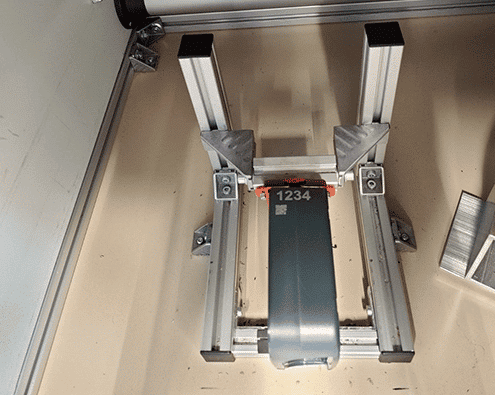

Our permanent marking solutions using dot peen and laser engraving are perfectly suited to the production of Datamatrix and QR code markings. Our vision equipment can also read Datamatrix codes for traceability integrated into your automated processes.

Datamatrix code: the ideal industrial traceability solution

It’s no coincidence that Datamatrix code marking has become widely used in many industries. This is due to a number of advantages:

Information capacity

This is the 2D code format that can record the most data. Up to 50 characters can be encoded on a 6mm-wide Datamatrix. It can record up to 2335 alphanumeric and 3116 numeric characters.

Resistance and durability

Thanks to repeated marking, the Datamatrix code can be read despite damage of up to 33%. The repetition of the pattern enables information to be duplicated, guaranteeing total legibility.

Low running costs and rapid marking

The fact that a Datamatrix code can be applied to a very small area of the part optimizes production and reduces costs. It’s also easier to target a suitable area for permanent marking.

Datamatrix code marking: finding the most suitable equipment

Implementing Datamatrix marking production is fairly simple, whatever the use and equipment, whether in a portable configuration, on a workbench or on a production line. The most important thing is to maximize the quality of the marking, to make the 2D code as easy to read as possible. It may be necessary to test a number of parameters to find the right contrast and marking depth. Two effective technologies are recommended for this type of marking: laser engraving and dot peen marking.

Laser marking

The marking software that controls our Graphix.series laser station directly integrates a Datamatrix generator. All the operator has to do is enter the data to be integrated into the Datamatrix. He then easily selects the marking parameters from the materials database to obtain the best possible contrast, and the laser marking head takes over. Finally, you can start marking easily.

Dot peen marking

Technomark has developed a range of dot peen marking machines called Connect.series. Like all the functions in this range, Datamatrix code marking is very easy to use. Data is entered either manually or using a database.

The operator then selects the marking force of his dot peen machine according to the material to be marked, defines the marking depth, and launches the marking operation.

What’s the difference between a Datamatrix and a QR code?

Datamatrix and QR codes are quite similar in terms of functionality. The difference is in their use. The Datamatrix is much more widely used in the industrial sector, while the QR code is mainly used in marketing and communication.

The difference between them is technical. A QR code can contain more information, can be easily scanned by a smartphone and also includes non-European characters.

However, Datamatrix is often used for its space-saving benefits. Indeed, it can have a smaller dimension than the QR Code. It’s also much more secure, as it’s less easy to pirate. Moreover, Datamatrix has a higher acceptable 2D code damage rate than QR code, making it the most resistant of 2D codes.

How to read a Datamatrix code ?

A Datamatrix code, frequently used in industrial marking, is read using a suitable scanner. This compact 2D code contains essential information such as traceability or management data. The decoding process requires the scanner to be positioned at an appropriate distance from the code, ensuring clear visibility. Once captured, the data is converted electronically for fast, accurate interpretation. This technology offers an efficient solution for automatic data reading, optimizing industrial product tracking and management processes.

How to create a Datamatrix code

The creation of a Datamatrix code, essential for industrial marking, requires the use of 2D code generation software. These programs can be used to encode information such as serial numbers, dates and other specific data. Once the information has been entered, the software generates the corresponding Datamatrix code. This can then be integrated into an industrial marking machine, such as those using dot peen or laser, to permanently print the code on the desired surface. In this way, the process of creating a Datamatrix code combines precision, flexibility and ease of integration to meet the varied needs of industrial marking.

Discover our Datamatrix applications