COMBO

2-in-1 dot peen marking station*: bench and portable configuration

Don’t choose between reliability and versatility

*Patented and protected software

Why COMBO is made for you?

2 in 1 equipment

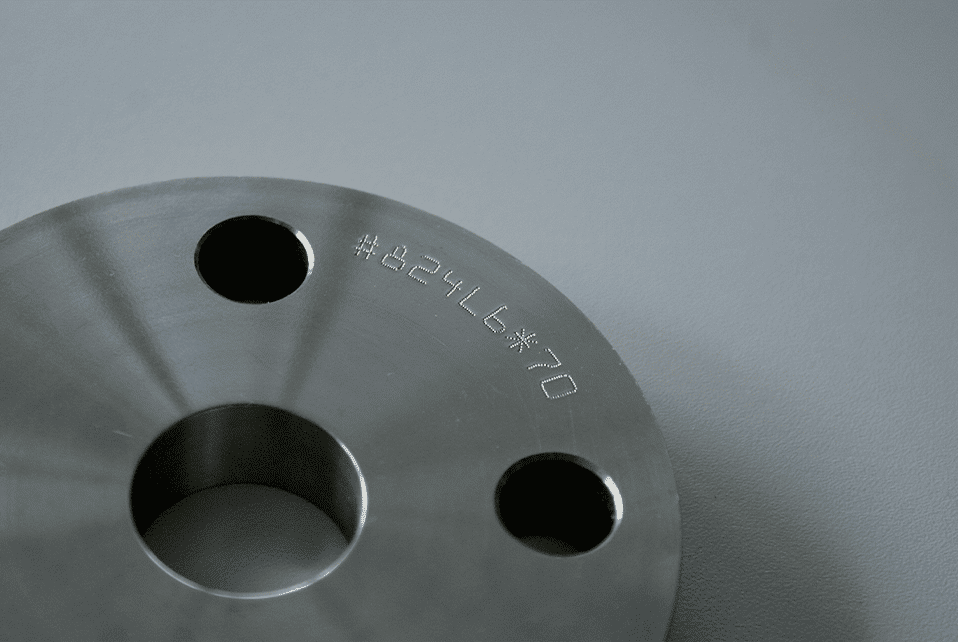

The Combo marking solution has taken the versatility of dot peen to the next level. Combo combines a portable and a bench mode in one machine, with a change of configuration in less than 10 seconds without tools.

Bench mode: fixing the marking head to an easily adjustable column. Ideal for small to medium sized parts.

Portable mode: operator travels with the wireless marking head within a 10 metre radius of the marking station. Ideal for medium to large, heavy or hard to reach parts.

Network connected

In addition to being able to create your own marker files on the controller, Combo allows you to easily import and export all your data.

Enter the Industry 4.0 era.

Wireless

To offer maximum freedom, the marking head is connected directly to the controller via a secure Wi-Fi connection. The pairing between the two is very easy thanks to RFID technology.

In its portable configuration, the Combo equipment allows you to mark within a 10 metre radius of the control unit. Combo offers a whole new experience that is unprecedented in the industrial marking market.

parts of all sizes

small and medium series

intelligent Driving Impact (IDI)

360° use

Multiple accessories

lighting of the marking area

the versatility of dot peen marking

Fast and flexible

- Change of configuration in 10 seconds without tools

Lithium ion battery

High performance NMC type

3 consumption modes :

- 100% electric

- 100% battery

- Plug-in hybrid

Optimised ergonomics

- Lightweight and easy to install marking head

- Quick Shift function for quick height adjustment

- Easy to grip thanks to its in-line handle

5 in 1 support foot

- Marking flat parts,

- Magnetic support,

- Non-slip,

- Marking of cylinders,

- Positioning aid

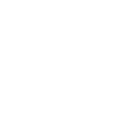

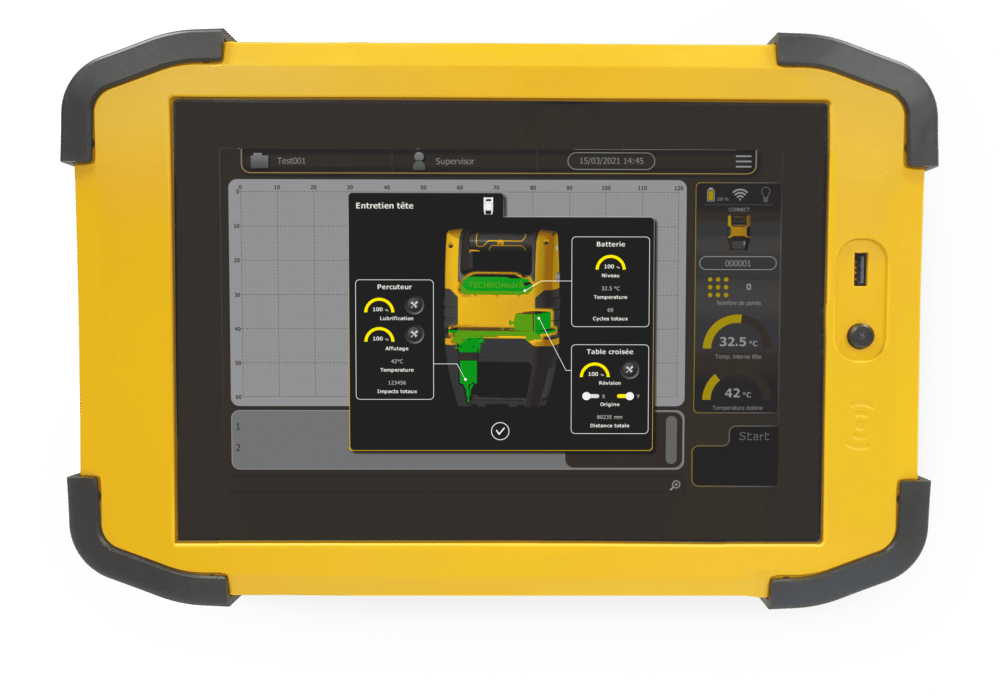

Intelligent and intuitive software

- Preventive maintenance

- Dashboard customisation

- Marking in 3 clicks

- Marking information in real time

- Access management and connection of marking heads by RFID chip

- Multilingual software

- Easyshift function for marking positioning assistance

Applications and Technical Specifications

| Distance between head and controller | 10 metres |

| Marking window | 120x60mm |

| Number of marking speeds | 3 speeds |

| Number of marking forces | 11 forces |

| Lithium ion battery | 22V |

| Max marking height | 290mm |

| Weight of head (with foot) | 3,1 kg |

| Screen |

10-inch tempered glass |

| Connectivity | 1 port Ethernet et 3 ports USB |

| Controller holder | Controller holder Universal VESA 100 fixing for 4 stand configurations |

| Protections |

4 protective bumpers and technical polymer shell |

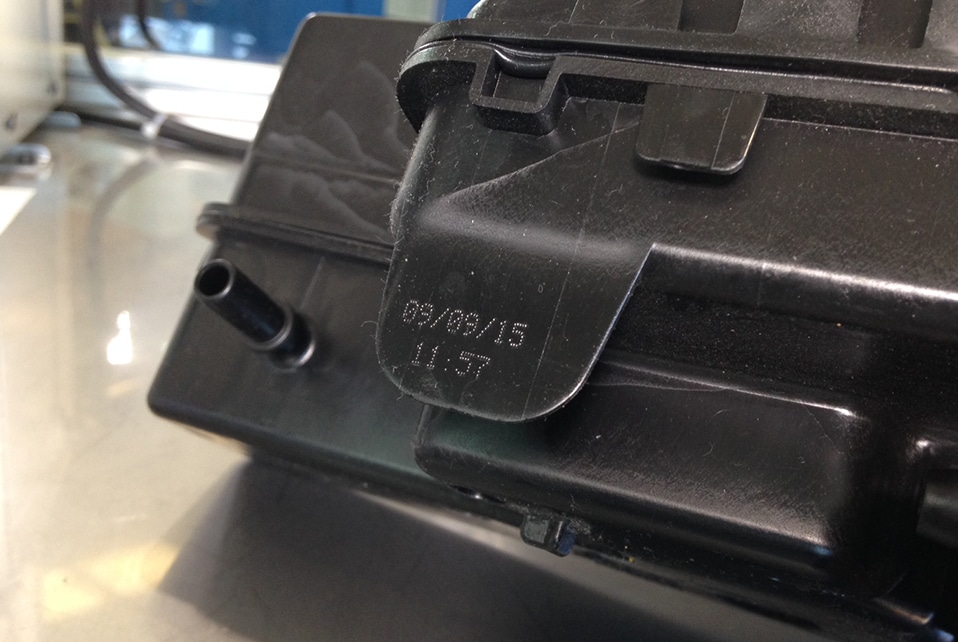

| Marking types |

Alphanumerical content |

| Straight marking |

Fixed text |

| Angled marking |

Sequential numbering |

| Radial marking |

Data import variable |

| Mirror marking |

Time and date stamp |

| 2D Barcode |

Graphic types |

| Datamatrix | Logo |

| QR Code | Shape |

| ECC200 | Symbol |

| Plastics | ||

| PVC | ● | |

| Polyamide | ● | |

| Polycarabonate | ● | |

| Polyethylene | ● | |

| Polypropylene | ● | |

| POM | ● | |

| Acrylique | ● | |

Non-exhaustive list, Request your free sample marking test

4 configurations according to your needs

Light

Light and compact controller holder

Advanced

Bench top parking and charging station

Upgraded

Controller holder fixed on the column

Full

Complete solution integrated on trolley

Find out more

Software

Technomark has developed its own software to accompany your dot peen marking machine and simplify your daily work.

USB Production Tracker license

Export of marked data

Font Creator license

Creation of custom fonts

Custom HMI license

Customisation of the dashboard and OLED screen

RFID – Log on head or control box license

Badge access

Vision

VISION

High performance proofreading system

using 1D and 2D code reader

Technomark’s high-performance barcode reader proofreading systems make it easy to identify a part. This tool meets the needs of production control and parts identification. In the industrial sector, marking often takes the form of OCR type characters or of 1D or 2D code, the 2D Datamatrix code ECC 200 being the best known and the most used.

Spare parts

Ordering spare parts

It is possible to order spare parts for each of our marking solutions. If necessary, do not hesitate to contact us by email or phone. We guarantee the availability of spare parts for up to 5 years after the end of life of our products.

Our network of partners allows us to be responsive and to offer fast lead times between order and delivery

Services

Our desire is to be proactive and to constantly seek solutions to improve the services offered to our customers.

Pre-sale

feasibility study

Showroom demonstration

Marking samples

Onsite testing

After-sales and repairs

Factory maintenance contract

Helpline

maintenance contract

equipement loan

repair

Customization

ADVISE AND SUPPORT YOU

Technomark helps you build a cost effective marking solution that is perfectly suited to your needs

REQUEST YOUR FREE

QUOTATION – DEMO – DOCUMENTATION