All-in-one laser station* with on-board camera, material database and multi-level function

*Developed by Technomark

Why GRAPHIX is made for you ?

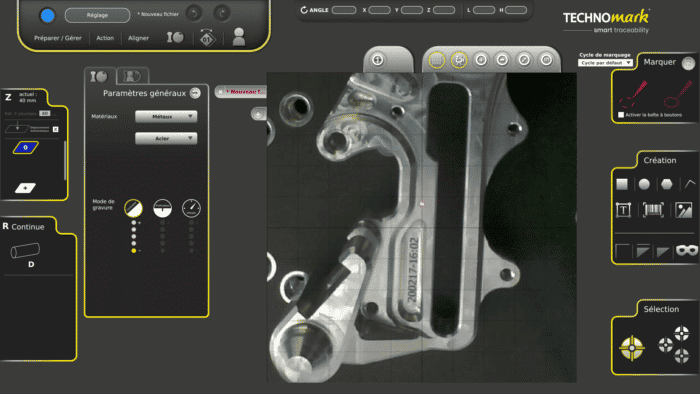

Smart View function

The Smart View function is a revolution in this new generation of laser station. The camera integrated in the marking head allows you to view the workpiece directly on the screen. You can now place and view your marking directly on the part. This makes marking set-up faster and reduces error rate.

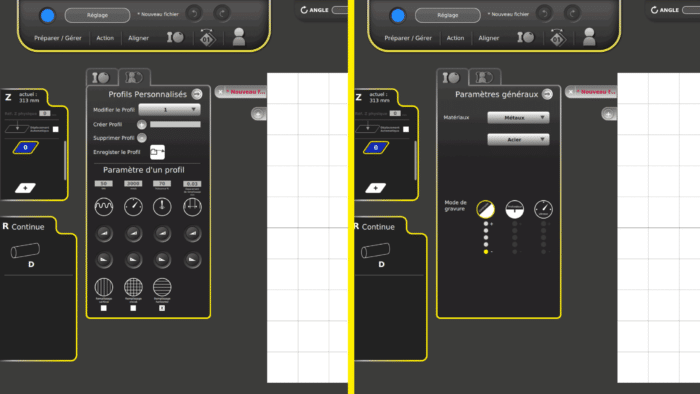

Materials database

It offers the possibility for novice users to set up markings without having any special knowledge of laser marking.

Marking in 2 steps:

- 1. Selection of the material to be marked

- 2. Definition of the marking result according to three characteristics: depth, contrast or speed

But if you are a qualified operator, you can also make more complex markings thanks to the advanced settings

Multi-level marking

The multi-level function optimises the efficiency of the marking production:

- Multiple markings on different heights of a workpiece in a single run as well as on curved surfaces

- Reduced number of actions and time savings

- Optimised ergonomics when combined with the Smart View function

fiber laser technology

small to medium sized parts

small to large series

several window sizes

lighting of the marking area

wide range of accessories

Customisation

The Graphix laser marking station has been designed to meet the many needs of our customers. Offering you a personalised service is very important to us in order to guarantee your complete satisfaction with our marking solutions.

All-in-one laser station for accessible marking to all

Assisted door opening

with two positions for easy loading of parts

Electric column

Digital control of the z-axis with a useful stroke of 400mm

Fiber laser head

High performance with on-board camera

Multiple options

Side openings (single and double), rotary axis, retractable drawer and fume extractor

Easy to use and optimised ergonomics

- Material database

- Multi-level marking

- Marking in 3 clicks

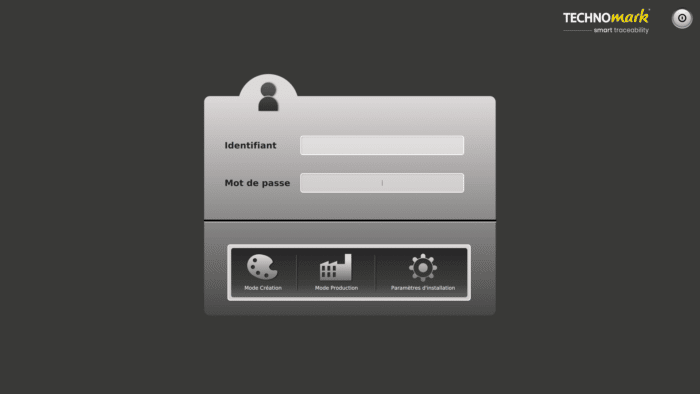

- Production and creation mode

- Multilingual software

- Preview of the marking on the part

Applications and Technical Specifications

| Marking windows | 100x100mm or 140x140mm |

| Scanning speed | 12m/s |

| Type of laser | Class 1 fibre laser in station configuration |

| Available powers | 20W, 30W and 50W |

| Screen |

21.5″ integrated in the station |

| Connections |

1 Ethernet port and 3 USB ports |

| Dimensions | W: 800mm, H: 985mm and D: 755mm |

| Loading capacity |

W: 500mm, H: 400mm and D: 500mm |

| Types of markings | Alphanumeric content |

| Straight marking | Text input |

| Angular marking | Serial number variable |

| Radial marking | Data import variable |

| Mirror marking | Time stamp variable |

| 1D and 2D code | Visual |

| Bar code | Logo |

| QR Code | Form |

| Datamatrix | Symbol |

| Plastics | ||

| PVC | ■ | |

| Polyamide | ■ | |

| Polycarbonate | ■ | |

| Polyethylene | ■ | |

| Polypropylene | ■ | |

| ABS | ■ | |

| Acrylic | ■ | |

This list is not exhaustive. Please note that some materials should not be marked with a laser solution. For more information, contact our laser experts and ask for your sample marking test

Find out more

Customisation

Customisation

ADVISE AND SUPPORT YOU

Technomark helps you build a marking solution that is perfectly suited to your needs and under competitive conditions

- Motorised electric door

- Customised side openings

- Y-axis movement of the marking head

- Rotating loading platform

- And many other solutions…

Vision

VISION

High performance proofreading system

using 1D and 2D code reader

Technomark’s high-performance barcode reader proofreading systems make it easy to identify a part. This tool meets the needs of production control and parts identification. In the industrial sector, marking often takes the form of OCR type characters or of 1D or 2D code, the 2D Datamatrix code ECC 200 being the best known and the most used.

Spare parts

Ordering spare parts

It is possible to order spare parts for each of our marking solutions. If necessary, do not hesitate to contact us by email or phone. We guarantee the maintenance of spare parts for up to 5 years after the end of life of our products.

Our network of partners allows us to be responsive to limit the waiting times between order and delivery.

Services

Our desire is to be proactive and to constantly seek solutions to improve the services offered to our customers.

Avant-vente

feasibility study

Showroom demonstration

Marking samples

On-site testing

Après-vente et réparations

factory maintenance contract

helpline

maintenance contract

equipement loan

repair

Customization

REQUEST YOUR FREE

QUOTATION – DEMO – DOCUMENTATION