Technomark > Connect.series care and maintenance

Connect.series care and maintenance

Cleaning and lubricating of the impact unit

- Remove the support foot (only for 120 marking heads).

- Unscrew the stylus guide.

- Remove the stylus guide, stylus, spring and core.

- Using the brush, clean the inside of the impact unit.

- Using a cloth, clean the core, spring and stylus.

- Using the dock, check the spring condition (minimum length 39.5mm / 1,53inches).

- Check the O-ring condition around the stylus guide.

- Using the brush and a blowgun, clean the stylus guide.

- Reassemble the 4 pieces before screwing it back onto the impact unit.

- Pull the stylus to lubricate it. One drop only.

- Pull and rotate the stylus several times to distribute the oil properly.

- Release the stylus and wipe the excess oil from the stylus.

- Reinstall the support foot on the marking head (only for 120 marking heads).

Order your NPC-601 cleaning and lubrication kit through your dedicated contact

When should the impact unit be cleaned and lubricated?

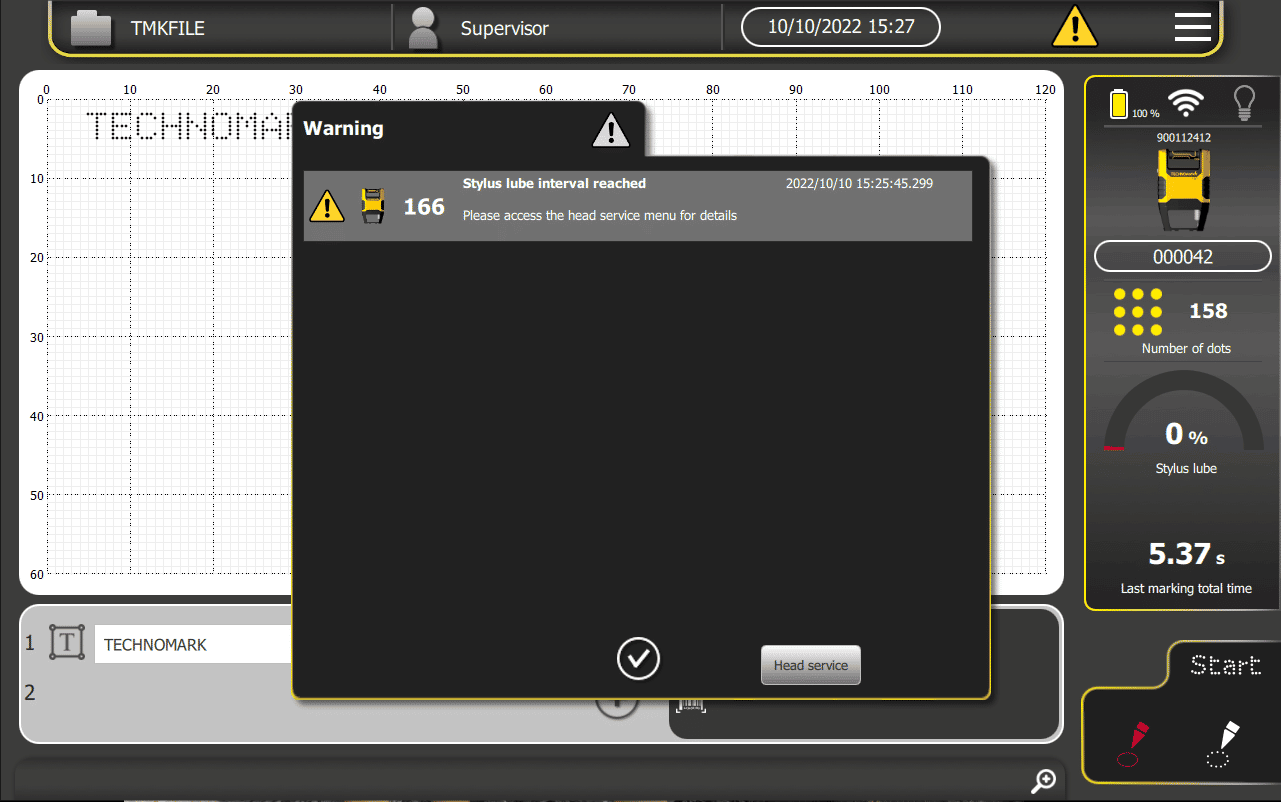

The procedure should be executeded every 750,000 impacts. The Connect.series software will notify you when this is required.

| Number of marking per day |

Font used

|

Cleaning and lubrication frequencies* |

| Low use |

20 |

5×7 |

Once a month

|

| 9×13 |

Once a month |

| Vect 0.2 |

Once a month |

| Vect 0.4 |

Once a month |

| Moderate use |

100 |

5×7 |

Once a month |

| 9×13 |

Once a month |

| Vect 0.2 |

Once a week

|

| Vect 0.4 |

Once a month |

| Intensive use |

200 |

5×7 |

Once a month |

| 9×13 |

Twice a month |

| Vect 0.2 |

Once a week |

| Vect 0.4 |

Twice a month |

| Very intensive use |

300 |

5×7 |

Once a month |

| 9×13 |

Once a week |

| Vect 0.2 |

Once a week |

| Vect 0.4 |

Twice a month

|

* These recommendations are only guidelines. It may be necessary to realize the procedure at shorter frequencies depending on the environment of use (excessive presence of dust, oil, …). Please refer to the advice of our teams.