Technomark > VIN number marking

VIN NUMBERS

What is a VIN number in the automotive sector?

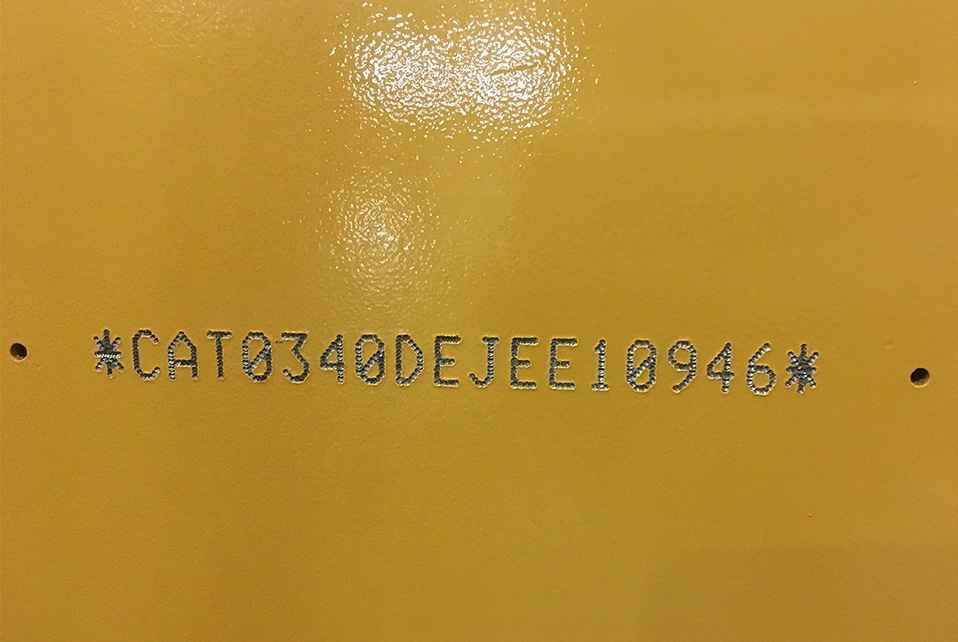

A VIN number, or Vehicle Identification Number, is a unique 17-character alphanumeric code assigned to each motor vehicle. It acts like a car’s fingerprint, providing a unique identity for each vehicle produced. The VIN number contains essential information such as country of origin, manufacturer, model, engine type and much more. The VIN number is used to identify, trace and secure vehicles throughout their life cycle.

VIN number regulations

VIN marking is regulated by strict standards to guarantee vehicle traceability and safety. Regulations require that the VIN number be clearly and durably marked on certain parts, such as the vehicle chassis or engine. Compliance with these standards is essential to combat vehicle fraud and identity theft, and to facilitate identification in the event of theft or accident.

VEHICLE TRACEABILITY

Car, motorcycle, truck… the need for vehicle traceability

Dot peen VIN marking offers numerous advantages for the automotive industry and regulatory authorities:

1. Traceability: enables a vehicle to be traced from manufacture to recycling, improving supply chain management and safety.

2. Fraud prevention: Reduces the risk of theft, illicit trafficking in stolen vehicles and vehicle identity theft.

3. Road safety: Facilitates the identification of vehicles involved in accidents, helping investigators and insurers to determine responsibility.

4. Certification of conformity: A correctly marked VIN number is essential to obtain homologation and certification of conformity, enabling vehicles to circulate legally.

5. Environmentally-friendly recycling: Promotes efficient recycling of end-of-life vehicles, as the VIN number identifies materials and components for proper disposal.

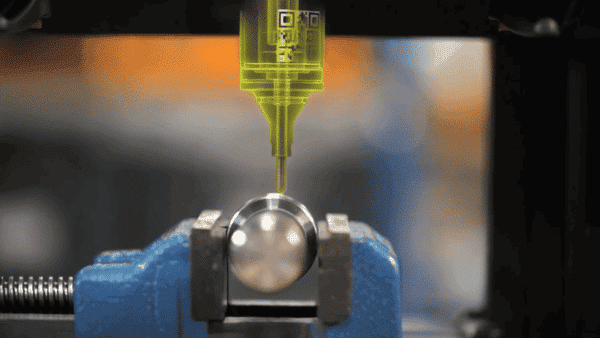

How VIN number marking works with dot peen machines

1. Precision and control: The dot peen marking machine is equipped with a very fine marking tip or needle. This tip is controlled with great precision by the marking head to create sharp, long-lasting characters.

2. Controlled impact: When the marking tip is in contact with the metal surface, it makes small, rapid and precise impacts, creating the characters of the VIN number. The depth of the engraving is controlled to ensure durability without damaging the part.

3. Permanent and legible: The result is a permanent and legible marking, resistant to wear, weather and handling. The characters remain clearly visible throughout the life of the vehicle, contributing to traceability and safety.

VIN dot peen marking is a reliable solution for guaranteeing vehicle traceability and safety. Make sure you comply with current regulations and choose quality marking equipment for optimum results.

Are you an automotive manufacturer or an industry player? To find out more about our expertise in dot peen VIN number marking and our high-quality products, please contact us. We’ll be delighted to answer your questions and support you in your automotive marking needs.

Contactez nous !

How to engrave a chassis number?

- Material preparation: Make sure you have the appropriate tools, including an industrial marking machine, templates or guides if necessary, and the material to be engraved.

- Surface preparation: Thoroughly clean the surface of the chassis to remove any dirt, grease or other impurities that could interfere with the engraving process.

- Frame number selection: Make sure you have the correct frame number, and set up the marking machine accordingly.

- Precise positioning: Position the marking head precisely on the chassis, using the appropriate guides to ensure that the engraving is correctly positioned.

- Engraving: Activate the marking machine and let it perform the engraving. Be sure to follow the recommended settings for the engraving method you are using.

- Verification of engraving: Once engraving is complete, inspect the chassis number to ensure that it is clearly legible and correct.

- Protection: Finally, consider applying protection, such as a coating or sealer, to preserve the durability of the engraving.

How to decrypt a VIN number?

- The first 3 characters indicate the manufacturer’s code (e.g.: VF3 represents Peugeot).

- Characters 4 to 8 provide vehicle composition information.

- Character 9 represents the vehicle equipment code.

- Character 10 indicates the vehicle’s year, using letters from A (corresponding to 2010) to Z, then numbers.

- Character 11 is the vehicle code.

- Characters 12 to 17 form a sequence of numbers that uniquely identify the vehicle.

This VIN coding is used to provide specific vehicle information, such as manufacturer, model, year of manufacture, equipment and a unique serial number.