Discover our fiber laser engraving solutions

Laser marking

Graphix

Fiber laser marking station with on-board camera

- Smart View function

- Materials database

- Multi-level marking

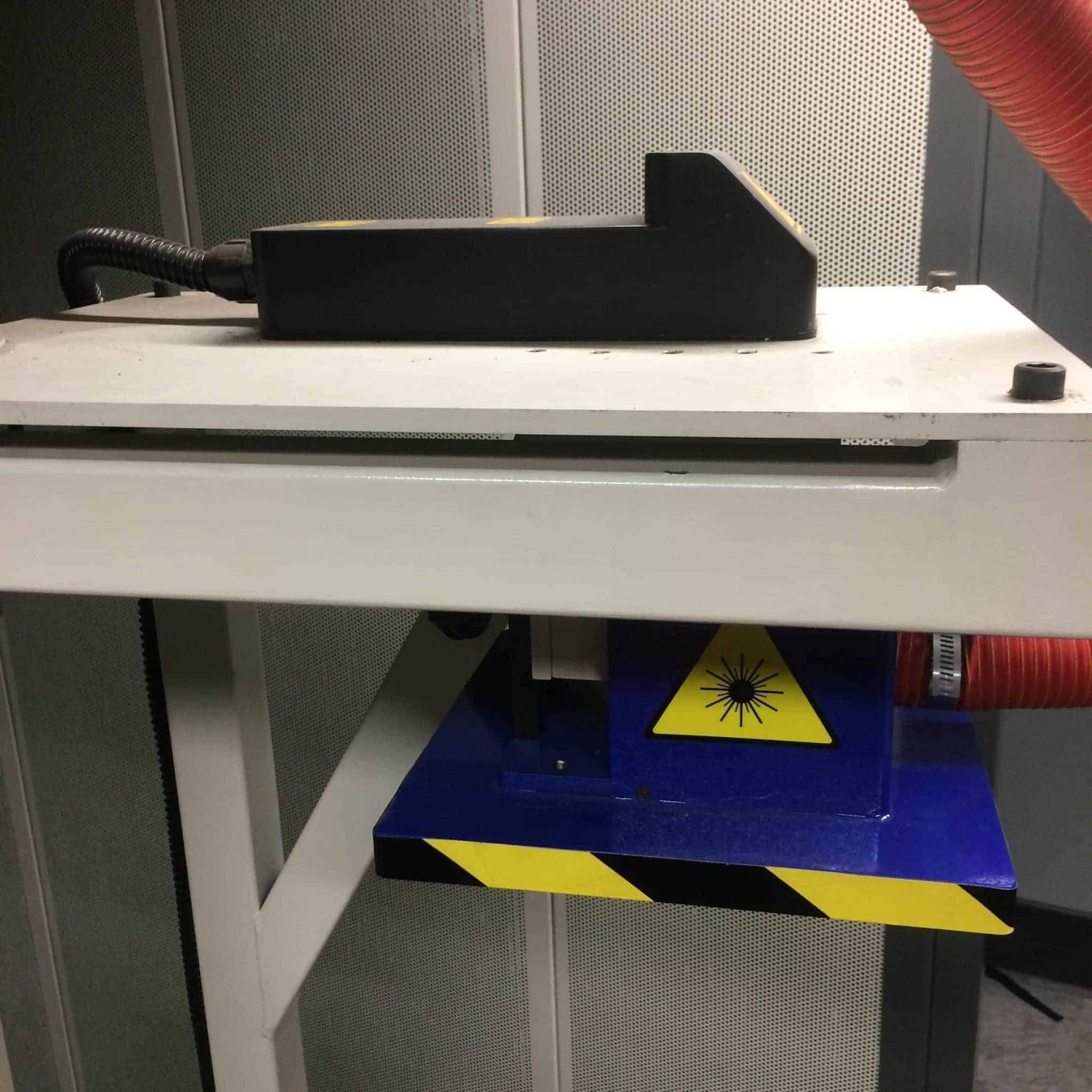

Graphix inline

Fiber laser engraving solution integrated into a production line

- Automated processes

- Improved productivity

- Easy to integrate

Industrial laser engraving machine for metal, steel, aluminum, stainless steel and plastics

- Optimized technology for aesthetic marking thanks to precision and thinness

- Marking capability on a large list of materials

- Designed for stationary and integrated use, to suit a wide range of needs

- Numerous marking options (variable texts, logos, Datamatrix, etc.)

Does this technology meet your needs?

LASER MARKING

Laser engraving and marking

Technomark offers permanent marking solutions based on laser technology. The ergonomics and compactness of Technomark’s range of laser marking machines have been designed for easy use in the workshop.

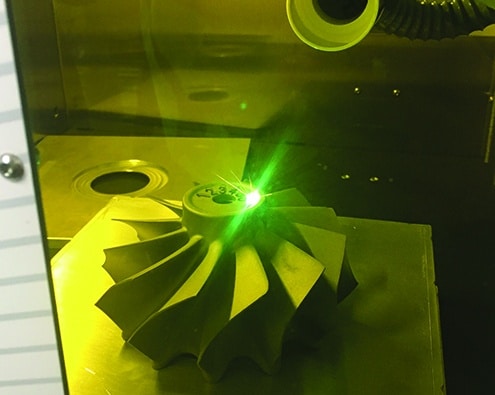

Our laser marking machines are equipped with fiber technology for fast, precise marking on all types of materials. They are mainly used for marking medium to high-speed production runs, for deep or light engraving, decoration and identification for traceability of any part.

Equipped with optional 360° rotary axes, our laser engravers can also mark in any position. Available in an integrated version, laser marking is also available for your production lines..

The integrated laser marking equipment enables extremely fast, high-quality engraving on a wide range of materials. Its compact design makes it easy to integrate on your production lines..

L’équipement de marquage laser intégré permet une gravure extrêmement rapide et de grande qualité sur un large choix de matériaux.

What is laser engraving?

The principle of industrial traceability by laser engraving is based on a high-intensity, high-fine beam focused and directed at the part to be marked.

Its orientation is ensured by a galvanometric head composed of two mirrors. Laser marking is contactless and universal on all types of surfaces: plastics, metals, ceramics, etc.

Bleaching

Material bleaching is a chemical reaction caused by the heat of the beam. The shades produced depend on the material.

Removal

This method removes the top layers of materials to create precise markings and color contrasts. Commonly used materials include anodized aluminum, lacquered metals, films and laminates.

Foaming

Foaming in industrial engraving involves the melting of material by the laser beam to produce clear designs on opaque plastics.

Annealing marking

This technique alters the color of the surface using the heat of the laser beam (via oxidation).

How does laser marking work?

Laser engraving consists in applying a permanent marking to various materials, such as metals and certain plastics, using a laser beam. Industrial laser marking can be used to engrave barcodes, serial numbers or batch numbers.

We offer a range of fiber laser marking systems (for stationary use, installed on a workbench or integrated into a production line). The laser beam is directed at the part you wish to mark, whether for deep or light engraving.

What are the advantages of a laser marking station?

Laser marking technology is one of the most common solutions for permanent marking. Depending on your marking applications, a laser engraver may be the right choice.

Different types of marking are possible with a laser station:

- alphanumerical marking

- marking of timestamps and other variables

- Datamatrix and barcode marking

- marking of logos and visuals

The list of advantages of laser marking is long. Compared with other machine ranges, this solution offers fast, highly precise marking. Moreover, a wide range of accessories can be used to create complex markings to suit the shape, size and materials of the parts to be marked.

In particular, our Graphix.series laser station range offers customized solutions. For example, a rotary axis for marking cylinders, a fume extractor, or customized side openings for engraving long parts.

Technomark is a specialist in the conception and manufacture of industrial marking machines. Take advantage of the advice of our experts in permanent marking and traceability to define the right equipment for your needs.

Technomark laser engraving solutions

| Graphix | Graphix Inline |

|

|---|---|---|

| Technology | Laser | Laser |

| Range | Graphix.series | Graphix.series |

| Marking window |

100x100mm et 140x140mm | 65x65mm , 100x100mm, 140x140mm et 180x180mm |

| Use | Station | Integrated |

| Network connection | Yes | Yes |

| Wavelength | 1.064 µm | 1.064 µm |

| Release year | 2021 | 2016 |

| Laser source |

Fiber | Fiber |

| Available powers | 20W 30W et 50W | 20W |

| Configuration (EN 60825-1 standard) | Class 1 | Class 4 |

What materials can laser marking be applied to?

The infrared wavelength of Technomark’s laser engraving solutions enables high-quality marking of :

- All metals (aluminum, steel, painted and chromed steel, stainless steel, bronze, carbide, titanium and titanium alloys, nickel and nickel alloys).

- Most plastics (polyamide, polypropylene, ABS).

What types of marking are possible?

With Technomark laser engraving machines, you can easily mark all types of information with precision and high quality:

- Alphanumeric characters and plain text

- Time stamps, serial numbers

- Bar codes

- QR codes, 2D Datamatrix

- Logos, symbols, images, etc.

What are the applications for laser engraving?

The main sectors for which Technomark provides traceability are: automotive, aeronautics, energy, metallurgy, medical, as well as many other fields (agriculture, agri-food, defense, electronics, railways, lifting and public works, mechanics, motorcycles, heavy goods vehicles).

Datamatrix marking enables the traceability of many components, such as :

- Surgical instruments

- Jet engine blades

- Aircraft engines

- Truck tanks

- Turbocompressors…

How to choose a laser engraver, which engraver to buy?

When choosing a laser marking machine, it’s important to consider several factors, including the type of laser, the size of the work area and the type of materials to be marked. It’s also important to know the precision and engraving speed required, as well as the type of control and software needed to operate the machine.

- Graphix: suitable for all profiles thanks to its material database, multi-level marking and ergonomic software.

- Graphix Inline: a low-maintenance engraving machine for medium and large production runs.

Discover our examples of laser marking applications