Technomark > Marking and engraving on aluminum

Marking and engraving on aluminum

Marking applications on aluminum

Marking and engraving on aluminum

Aluminum is a very common metal. Malleable and not very dense, it is a silvery-gray metal that does not alter very much in air. Some aluminum has surface coatings to improve resistance, but these do not exclude permanent dot peen and laser engraving.

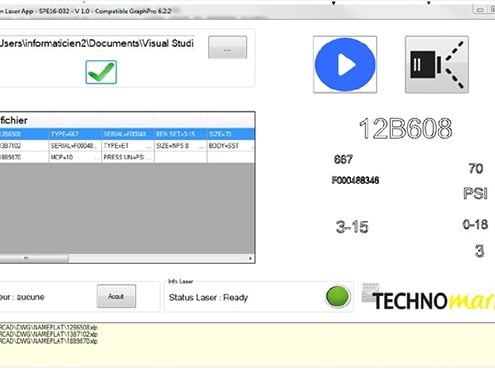

Technomark Marking can produce laser and micro-percussion markings using its aluminum engraving techniques, without altering the properties of the parts, unlike chemical engraving. “Ablation” engravings range from superficial to deep (from 0.01mm to 2mm), and renderings can be light or dark, depending on the settings and the type of aluminum.

Don’t hesitate to share your marking and traceability project with our experts, so that together we can define the best solution for your needs.

Request marking samples

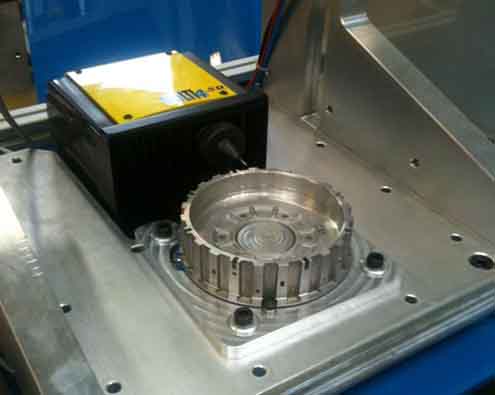

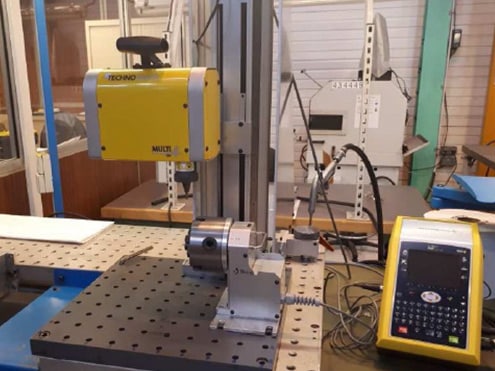

Dot peen marking on aluminum

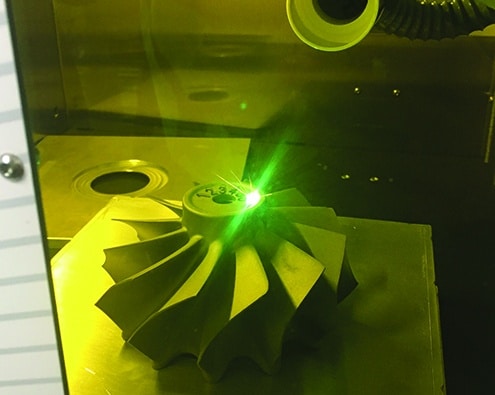

Contrasting laser engraving on aluminum

Dot peen engraving on aluminum

Dot peen technology is ideally suited to engraving aluminum. In fact, dot peen is a mechanical engraving technology that can produce markings on materials with a hardness of up to 63 HRC. Aluminum is less hard than this, and therefore tends to deform more easily than some other materials. This makes it easy to make deep markings quickly, without using the maximum force of your equipment. Recess engraving lets you add texture to your part with an aesthetically pleasing finish.

Laser technology for aluminum marking: embossed, black or thin.

Laser solutions are also ideal for marking aluminum parts. The different types of marking, whether annealed or material removal, work very well on aluminum parts to achieve high-contrast results. Moreover, renderings are even more contrasted when there is a coating on the part such as anodized aluminum, burnished aluminum or even painted aluminum. The laser can remove only the lightest layer to reveal the material in its raw state. This provides perfect legibility of the marking for easy proofreading by the operator or any other automated system.

What aluminum parts can be engraved?

Engravings can be made on metal, including aluminum parts, whatever the treatment and coating the part has received.

Many marking applications are quite common, as they are widely used by major companies in various sectors (automotive, aeronautics, metallurgy, etc.). We have, for example, the marking of manufacturer nameplates, which is essential for the distribution of certain products. This enables the manufacturer to insert a variety of information, such as its name and logo, the machine’s serial number, the various standards it respects, etc.

Here is a non-exhaustive list of examples of engraving on aluminum:

- Gearboxes

- Linear guides

- Camshaft housings

- Cylindrical aeronautical part

- Aluminum plate marking

Marking on treated and/or coated aluminum parts

Marking aluminum parts is a crucial step in the finishing process, with the aim of improving both the aesthetics and durability of components. Among the various coatings available, anodizing stands out by creating a protective oxide layer on the aluminum surface, offering corrosion resistance and an aesthetic finish. Zinc plating provides corrosion protection by depositing a layer of zinc on the aluminum surface. Nickel plating provides a bright finish while improving corrosion resistance. Polishing gives a smooth, shiny appearance, while chrome plating adds a layer of chromium for a tough, attractive finish. Sandblasting creates a matt texture by projecting abrasive particles onto the surface. Painting offers aesthetic personalization and additional protection. Finally, shot blasting involves projecting particles at high speed to clean the surface and improve adhesion of subsequent coatings. These various marking techniques contribute to the quality and appearance of aluminum parts, meeting the specific requirements of each application.

Discover our aluminum engraving applications

REQUEST YOUR FREE

QUOTATION – DEMO – DOCUMENTATION