EQUIP NOW

Dot peen marking

Buddy

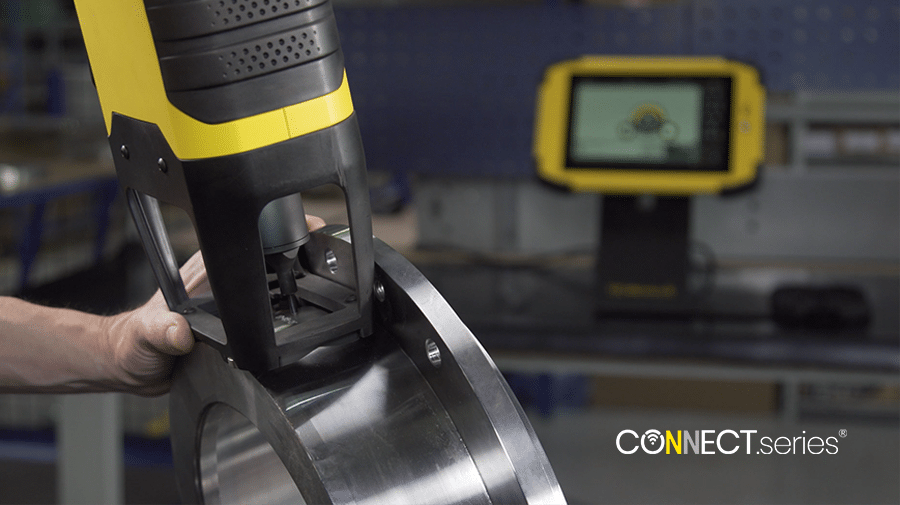

Smartphone-controlled dot peen solution

- Ultra-portable equipment

- Ergonomic application

- Optimized battery

Easy

Portable wireless dotpeen marking equipment

- Wireless connection

- Energy self-sufficient

- Network connected

Combo

Mixed dot peen machine: portable and benchtop

- Versatile equipment

- Network connected

- Customizable dashboard

M4inline

Integrated dot peen marking solution

- Automated processes

- Predictive maintenance

- Easy installation

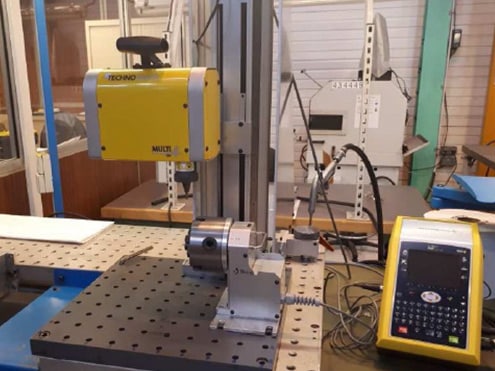

Multi4 portable

Portable dot peen marking equipment

- Nomadic solution

- Robust equipment

- Numerous accessories

Multi4 combo

Mixed dot peen machine: portable and benchtop

- Versatile solution

- Robust equipment

- Wide range of accessories

Technomark dot peen marking solutions

| EASY | COMBO | BUDDY | M4 INLINE | MULTI4 PORTABLE | MULTI4 MIXTE | MULTI4 ÉTABLI | |

|---|---|---|---|---|---|---|---|

| Technology | Dot peen |

Dot peen | Dot peen | Dot peen | Dot peen | Dot peen | Dot peen |

| Range | Connect.series | Connect.series | Connect.series | N/A | Multi4 V3 | Multi4 V3 | Multi4 V3 |

| Marking window |

60×30 – 120×60 | 120×60 | 60×30 | 50×55 – 120×55 – 200×55 | 50×60 – 120×60 – 200×60 | 50×60 – 120×60 | 50×60 – 120×60 – 200×60 – 200×200 |

| Use | Portable | Mixed | Portable | Integrated | Portable | Mixed | Benchtop |

| Network connection |

Yes | Yes | No | Yes | No | No | No |

| Wireless communication |

Yes | Yes | Yes | No | No | No | No |

| Release year |

2021 | 2021 | 2023 | 2015 | 2012 | 2012 | 2012 |

| Marking head weight | Easy 60 : 2,8kg – Easy 120 : 3,2kg | 3,2kg | Buddy 60 : 2,8kg – Buddy 120 : 3,2kg | N/A | 4,48kg | 4,19kg | N/A |

| Available configurations | Light – Advanced – Premium | Light – Advanced – Upgraded – Full | Standard | Integration | Cart | Standard | Standard |

| Control unit |

10″ OLED touch screen | 10″ OLED touch screen | Smartphone screen |

HD screen 640x480px | HD screen 640x480px | HD screen 640x480px | HD screen 640x480px |

The choice of high-performance, versatile equipment

Technomark is a leading manufacturer of dot peen marking machines. Our machines are characterized by :

- precision

- reliability

- ease of use

They are conceived to offer high precision and long life, making them an excellent choice for all industrial sectors.

Why choose dot peen marking technology?

- Material deformation makes marking permanent

- Able to mark a wide range of materials

- Generates no material chips or breakage sources on the part

- Versatile technology available in mobile, station and integrated versions

Does this technology meet your needs?

Dot peen marking solutions for mobile use

Do your employees need to move around to carry out permanent marking inside or outside your facility? Our portable dot peen marking solutions are designed primarily for marking medium to large parts that are sometimes difficult to access.

Dot peen marking solutions for stationary use

Do all your parts to be marked converge on marking equipment mounted on a bench? In this configuration, traceability is generally achieved on small to medium-sized parts, but may occasionally require portable mode for heavier, bulkier parts. Discover our dot peen marking solutions dedicated to stationary use.

Dot peen marking solutions for integrated use

Do you need to integrate a marking solution into your production line and automated processes? Simplify your traceability processes with our permanent micro-percussion marking solutions for integrated use.

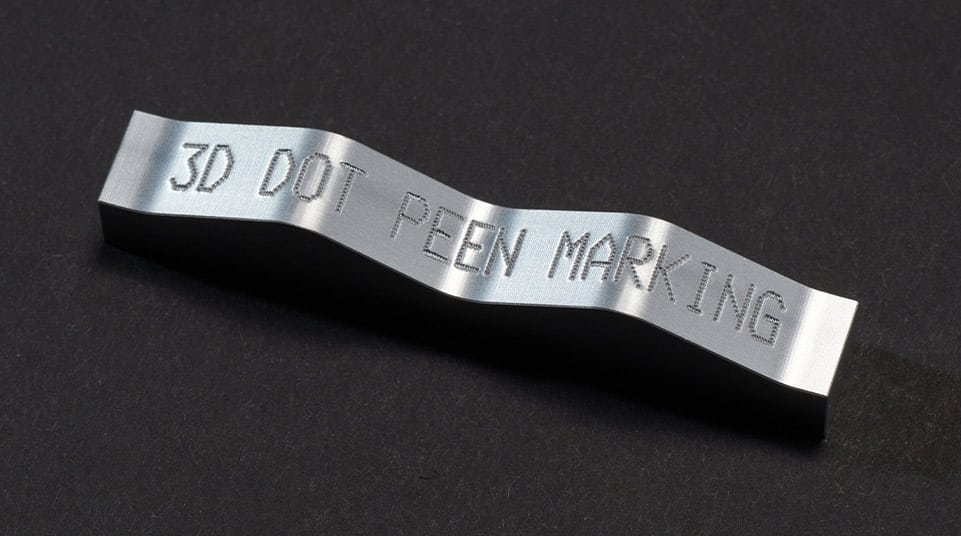

What is dot peen engraving?

It’s a technology based on the deformation of the material by a succession of impacts that form the permanent marking.

Technomark uses electromagnetic technology for its solutions. This mono-energy technology enables rapid, deep micro-percussion marking of all types.

The different ranges of solutions enable permanent marking on heavy, bulky and difficult-to-access parts, as well as on small, lightweight parts. Dot peen marking is precise and high quality in all positions and on all types of parts with a hardness below 63 HRC.

Equipped with a tungsten carbide stylus, which strikes the part, creating a material displacement that has the advantage of not chipping or generating breakage. With this technology, we can mark a range of alphanumeric characters, plain text, symbols, logos, QR codes and 2D Datamatrix.

Firstly, the permanent marking is created via the control unit, thanks to the integrated design software developed by Technomark. Next, the mechanical engraver is responsible for creating the mark, with a series of stylus impacts, all following an optimized trajectory but without moving the dot peen marking head.

Dot peen, ideal for permanent marking

Dot peen has many advantages: it’s extremely precise, fast, adaptable to different materials and repeatable, all of which ensure long-lasting engraving.

It guarantees permanent, unalterable marking, with variable, configurable depth, depending on requirements and the desired result.

For even higher marking quality, Technomark has developed the patented IDI* function. Embedded on all machines, this technology eliminates the difference in level between the part and the stylus.

*Intelligent Driving Impact

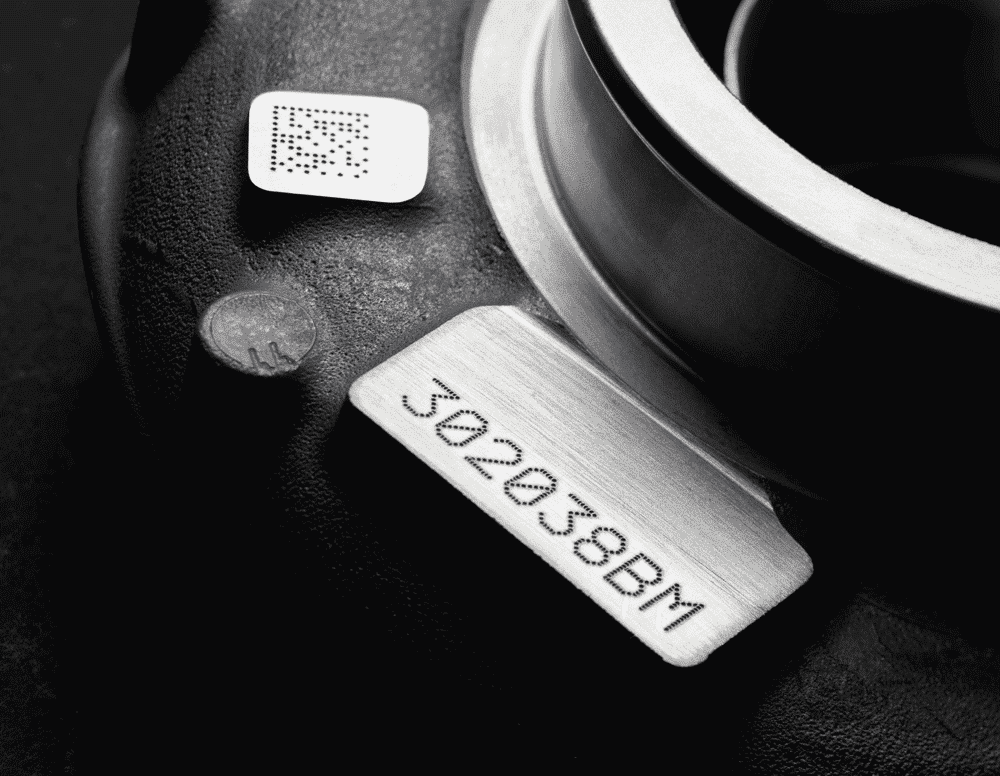

Datamatrix: the best type of marking for the automotive and industrial sectors

The automotive sector requires top-level quality and speed. Thanks to a type of marking such as Datamatrix, you’ll be able to meet these requirements.

You can guarantee traceability through marking:

- Engines

- Gearboxes

- Crankshaft

- Chassis

Which materials to mark?

Markings can be applied to a wide range of materials:

- aluminum,

- steel, painted and chromed steel, stainless steel, bronze, carbide, titanium and titanium alloys, nickel and nickel alloys

- some plastics (polyamide, polypropylene, ABS).

Please contact us for test marking to ensure the desired finish.

Micro impact: what can we mark?

With Technomark dot peen solutions, you can produce all types of permanent markings: alphanumeric characters and plain text, time stamps, QR codes and 2D Datamatrix codes, logos and simple symbols.

What are the sectors of application?

The main sectors for which Technomark provides traceability are: automotive, aeronautics, energy, metallurgy, medical, and many others (agriculture, agri-food, defense, electronics, railways, public works, mechanics, motorcycles, heavy vehicles).

Discover our examples of dot peen marking applications