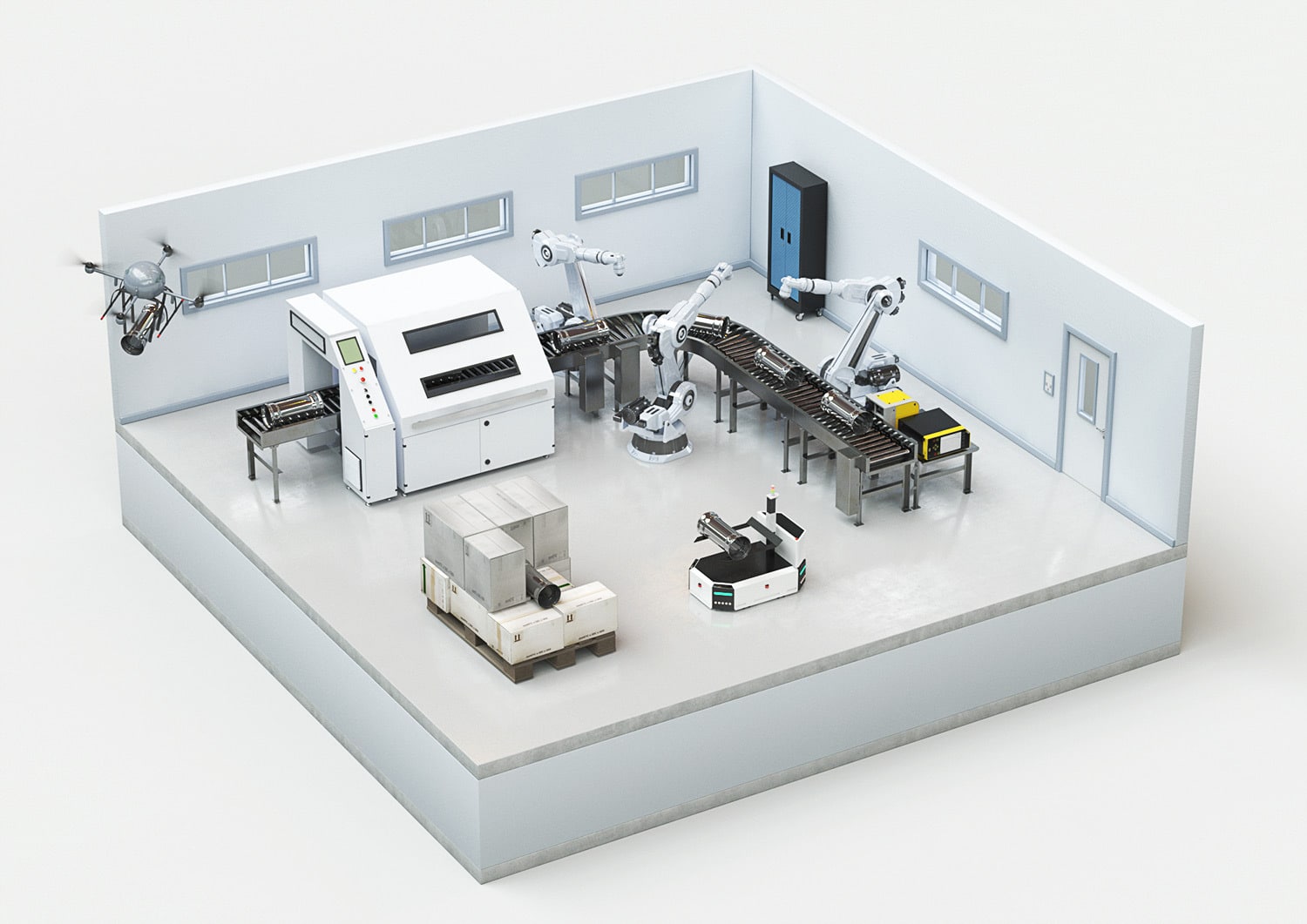

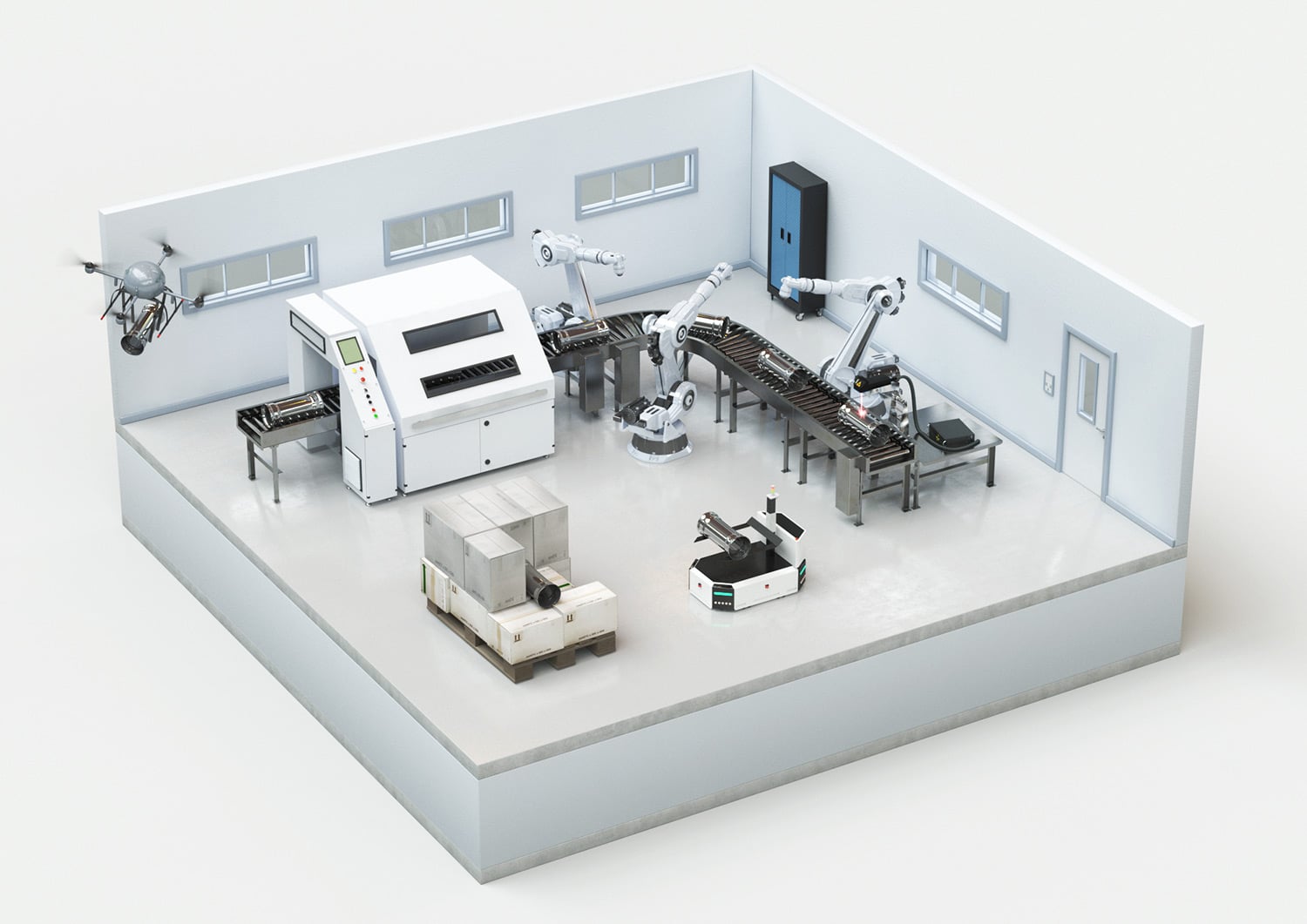

Integrated marking and traceability solutions

INTEGRATED MARKING, AUTOMATION

Dot peen marking integrated use

Dot peen marking integrated into your production lines

Your industrial use is said to be “integrated” if your industrial traceability solution is integrated into your production line. Our electromagnetic dot peen marking machines are designed to fit into your automated processes whatever the type and size of parts.

Discover our integrated Multi4 and M4 Inline dot peen marking products dedicated to this integrated use.

Integrated laser use

Laser marking designed for integration

Your industrial use is said to be “integrated” if your laser marking solution fits into your automated processes. We can engrave all types and sizes of parts thanks to our traceability equipment designed for this use.

Discover our Graphix Inline laser product dedicated to this integrated use.