A question often asked by manufacturers and professionals looking for high-quality marking solutions: how difficult is it to engrave stainless steel? Engraving alphanumeric sequences, serial numbers, special characters, logos, time stamps and codes such as datamatrix or QR codes is essential for effective industrial traceability.

Engraving stainless steel isn’t difficult with laser or dot peen marking

In this article, you’ll discover why stainless steel is particularly well suited to industrial marking, and especially to laser and dot peen marking, offering high-quality, permanent metal engraving without damaging the material’s surface.

We’ll also cover the composition of stainless steel, its advantages and disadvantages, and how to identify this material. The aim is to provide you with the information you need to choose the best marking solution for your industrial needs.

Finally, we’ll explore the technical and practical aspects of engraving on stainless steel, highlighting laser and micro-percussion marking technologies.

What is the composition of stainless steel?

Stainless steel is an alloy composed mainly of iron, chromium, and often nickel and molybdenum. Chromium is a key element, as it forms a passive chromium-oxide layer on the surface, giving the steel its corrosion resistance.

Stainless steels fall into four main families, each with its own characteristics:

| Family name |

Characteristics |

| Austenitic | Highly resistant to corrosion, good formability, often used in the food and medical sectors. |

| Ferritic | Good corrosion resistance, more magnetic, often used in automobiles and domestic appliances. |

| Martensitic | Hard and tough, but less resistant to corrosion, used for knife blades and tools. |

| Duplex | Combination of austenitic and ferritic properties, high corrosion and tensile strength, used in marine and chemical environments. |

What are the advantages of stainless steel?

Stainless steel offers many advantages for a variety of industrial applications:

- Corrosion resistance: thanks to its chromium content, it does not rust easily.

- Strength and durability: able to withstand heavy loads and resist wear.

- High-temperature resistance: maintains its properties even at high temperatures.

- Hygienic: easy to clean, ideal for the food and medical industries.

- Aesthetic: offers a smooth, glossy finish, enhancing the appearance of products.

- Recyclable: contributes to environmental sustainability.

What are the disadvantages of stainless steel?

Despite its many advantages, stainless steel also has certain drawbacks:

- Cost: generally more expensive than other steels due to its composition.

- Sensitivity to scratches and fingerprints: may require regular maintenance to maintain its appearance.

- Thermal conductivity: less efficient than other metals, which can be a disadvantage in certain applications.

- Weight: generally heavier than aluminum alloys or other light metals.

How can I tell if it’s stainless steel?

To determine whether a material is stainless steel, it’s important to consider its physical and chemical properties. Stainless steel is generally non-magnetic (although some ferritic and martensitic families are), has a smooth, shiny surface, and does not rust easily.

Chemical tests can also be carried out to identify the presence of chromium. In addition, it’s useful to know the different types of steel to make a clear distinction: carbon steels, alloy steels, tool steels and so on. Each of these types has specific characteristics and applications.

Metal engraving: the importance of professional equipment

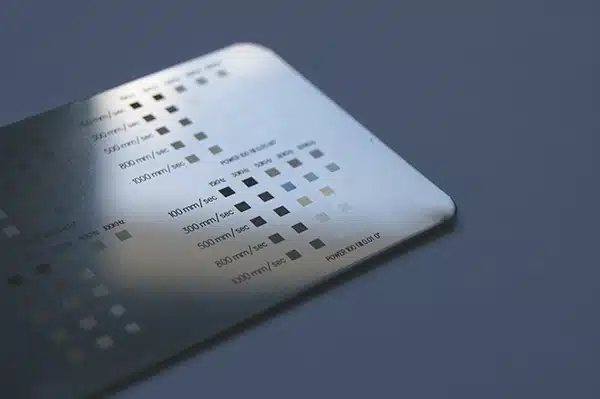

Engraving on metal, and particularly on stainless steel, requires professional equipment to guarantee long-lasting, high-quality results. Industrial laser and dot peen marking machines are designed for optimum precision and efficiency.

These technologies enable permanent marking that resists extreme conditions, such as high temperatures, corrosion and mechanical wear. By using professional equipment, you benefit from the clear, readable engraving essential for industrial traceability applications.

Moreover, these technologies are versatile and can be adapted to different metal types, thicknesses and shapes, offering a flexible solution for a variety of industrial applications.