The purchase of a metal laser engraving machine represents a significant investment for industrialists and professionals wishing to mark their products with precision and quality.

These machines, essential for industrial traceability, can engrave alphanumeric sequences, serial numbers, special characters, logos, as well as timestamps and various codes such as datamatrix or QR codes. But what price range should you consider for such a technology?

How much does a good metal laser engraving machine cost?

This article aims to inform professionals about the cost of a high-quality metal laser engraving machine . Investing in such a machine is not a decision to be taken lightly, given its direct impact on marking quality and, by extension, on a company’s brand image.

We’ll examine the various factors that influence price, such as laser power, precision, engraving speed, as well as additional features that may be crucial depending on your field of application.

In addition, we’ll explore how choosing the right machine for your specific needs can not only improve your production efficiency, but also contribute to better traceability management of your products. Finally, we’ll provide practical advice on how to choose the right machine for your needs and budget.

Laser marking, a professional affair

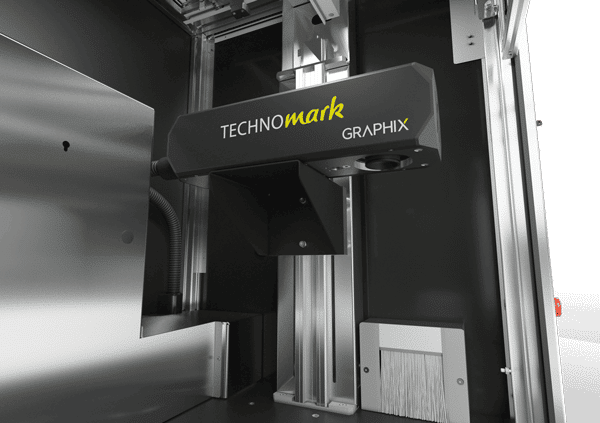

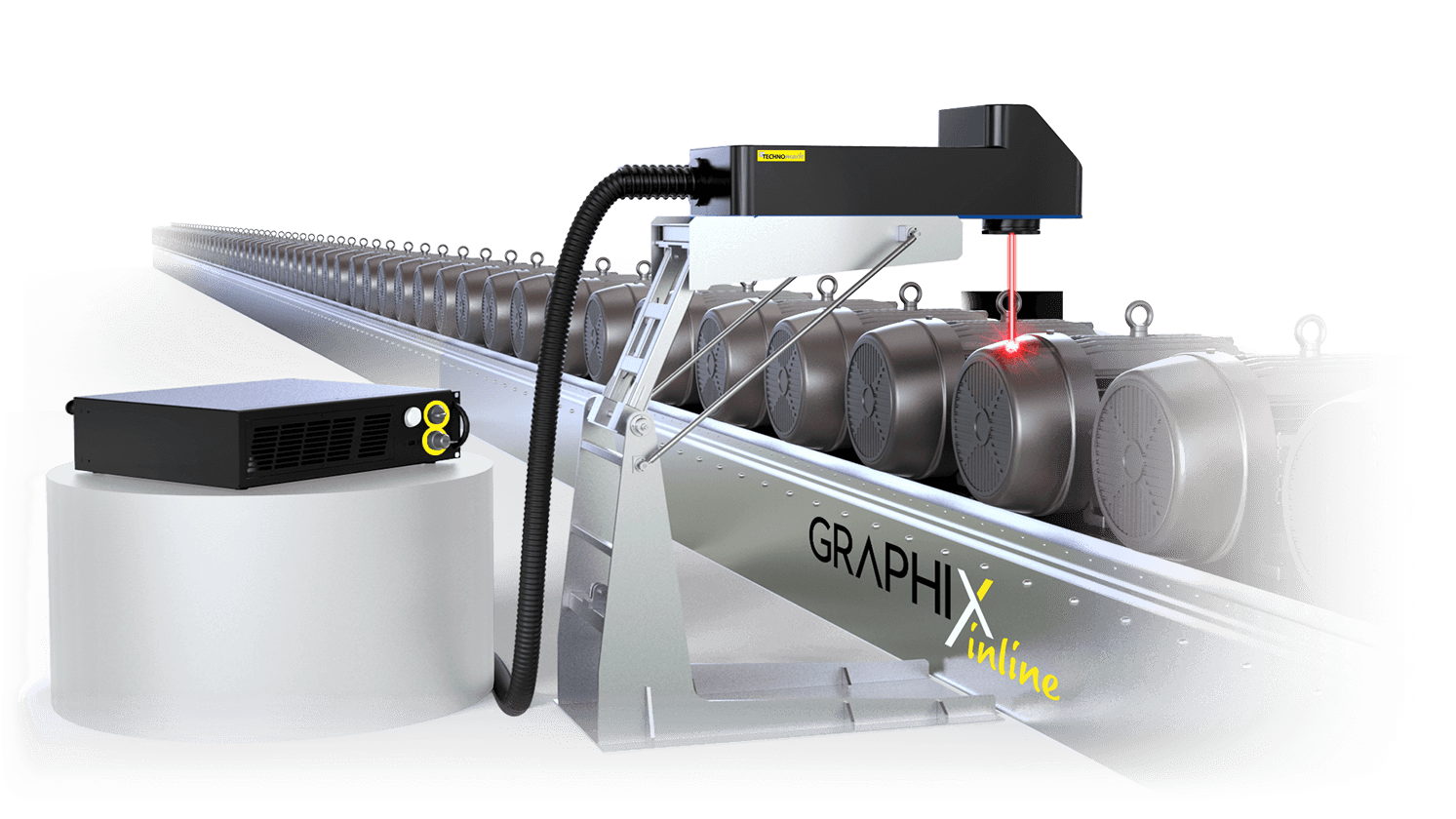

The purchase of a metal laser engraving machine should not be taken lightly by companies concerned about their image and the quality of their production. Opting for brand-name equipment such as Technomark guarantees not only superior performance, but also reliability and durability, which translate into an optimized return on investment.

Our metal lasers are designed to meet the most stringent marking requirements, offering unrivalled precision for engraving alphanumeric sequences, logos, and even complex codes such as datamatrix or QR codes.

The price of a quality laser engraving machine is justified by its direct impact on the fluidity of operations and the reduction of downtime, crucial elements in maintaining competitiveness in modern industry.

A reliable machine enables continuous production, avoiding costly disruptions due to breakdowns or poor-quality marking that could damage a company’s reputation. When you invest in a Technomark solution, you’re choosing recognized expertise in industrial performance.

For precise laser marking on metal

Laser engraving on metal, and more specifically on steel and stainless steel, represents a major challenge requiring extreme precision. Unlike wood, which is a relatively flexible material and easy to engrave, steel requires a much more rigorous approach, and equipment specifically designed to deal with its hardness.

Here are some key points to consider:

- Laser marking machine: The use of a suitable machine, capable of generating sufficient output power, is crucial to obtaining clean, precise results.

- Power output: The power delivered by the laser must be high enough to penetrate the steel, while remaining controlled to avoid damaging the material.

- Serial numbers: For engraving serial numbers or any other marking requiring high precision, it is essential to choose a machine offering excellent resolution.

Choosing the right equipment not only guarantees the quality and readability of the marking, but also the efficiency and reliability of the engraving process. In short, the success of such projects depends on cutting-edge technology specially designed to meet the challenges posed by materials as tough as steel.

Stainless steel offers numerous advantages for a variety of industrial applications:

- Corrosion resistance: thanks to its chromium content, it does not rust easily.

- Strength and durability: able to withstand heavy loads and resist wear.

- High-temperature resistance: maintains its properties even at high temperatures.

- Hygienic: easy to clean, ideal for the food and medical industries.

- Aesthetic: offers a smooth, glossy finish, enhancing the appearance of products.

- Recyclable: contributes to environmental sustainability.

Find our best marking machines

Our range of metal laser engraving machines represents excellence in the field. We offer a variety of machines to suit all needs and budgets, ensuring that you’ll find the ideal equipment for your specific applications. Our expertise translates into unique knowledge in the design of durable and precise marking solutions for metal.

- Know-how: Years of experience enable us to offer you machines of the highest quality, designed to meet the most stringent requirements.

- Training: Technomark is committed to providing comprehensive training to ensure you get the most out of your investment from day one.

- Maintenance: Our after-sales service ensures that your machine retains its efficiency and precision over time, giving you unrivalled peace of mind.

Every laser engraving machine we offer is the result of intensive research and constant innovation, ensuring that our customers benefit from the most advanced technologies at competitive prices. Whether you’re looking to engrave serial numbers, logos or any other marking on metal, Technomark is your trusted partner for a superior marking solution.

Giving an idea of the price of a laser engraving machine for metal is complicated for several essential reasons. Firstly, the specific needs of each customer vary considerably according to the nature of their project, the type of metal to be engraved, and the precision and speed required for their operations.

The diversity of possible applications requires very different machine configurations. What’s more, options and additional features, such as worktable size, laser power, and various accessories, also influence the final price.

At Technomark, we understand the importance of aligning the offer with the precise needs of each customer to ensure the best possible marking solution. That’s why we offer customized quotations. This approach enables us to analyze the customer’s requirements in detail and offer a commercial proposal that best reflects the requested specifications and available budget. Requesting a quote from Technomark is a simple and straightforward process, designed to ensure optimum customer satisfaction by precisely meeting their needs with a customized solution.